Want to prevent metal from rusting? Keep air and water away from it. Best ways? Cover it up (paint, oil), choose rust-resistant metals (like stainless steel), or keep the environment dry.

Key Takeaways (Quick Tips)

- Block It: Put something between metal and wet air. That’s the main trick.

- Coatings Work: Paint’s obvious. Powder coating is tough. Even oil helps sometimes. Zinc coatings (galvanizing) are great outside.

- Smart Metal Choice: Use stuff like stainless steel or aluminum if you can – they fight rust naturally.

- Dry is Good: Rust loves water. Keep metal dry, especially tools or things in storage.

- Design Helps: Don’t let water get trapped in corners or gaps. Let it drain off.

- Clean Up: Wipe things down, especially if they get wet or salty.

Table of Contents

Why Bother Stopping Rust?

You know that nasty reddish-brown stuff on old steel? Or how other metals get dull and pitted? That’s rust or corrosion. It looks bad, sure. But worse? It makes the metal weak. Tools break. Furniture falls apart. Cars get holes. Stopping it early saves you headaches and money later. Good news is, you can fight back. Lots of ways to do it.

Cover Up Strategy: Put a Barrier On It

Simplest idea? Don’t let the air and water touch the metal. Put a coating on top. Like a raincoat.

Paint? Yeah, Obvious Choice.

The most common way. You put paint on metal. Creates a seal. Usually needs two steps: primer first (helps paint stick, sometimes fights rust itself), then the color coat on top. Works on lots of stuff. Easy to do yourself. Just make sure you clean the metal really well first! And know that paint can get chipped or scratched. You’ll need to touch it up or repaint down the road. Use paint meant for metal!

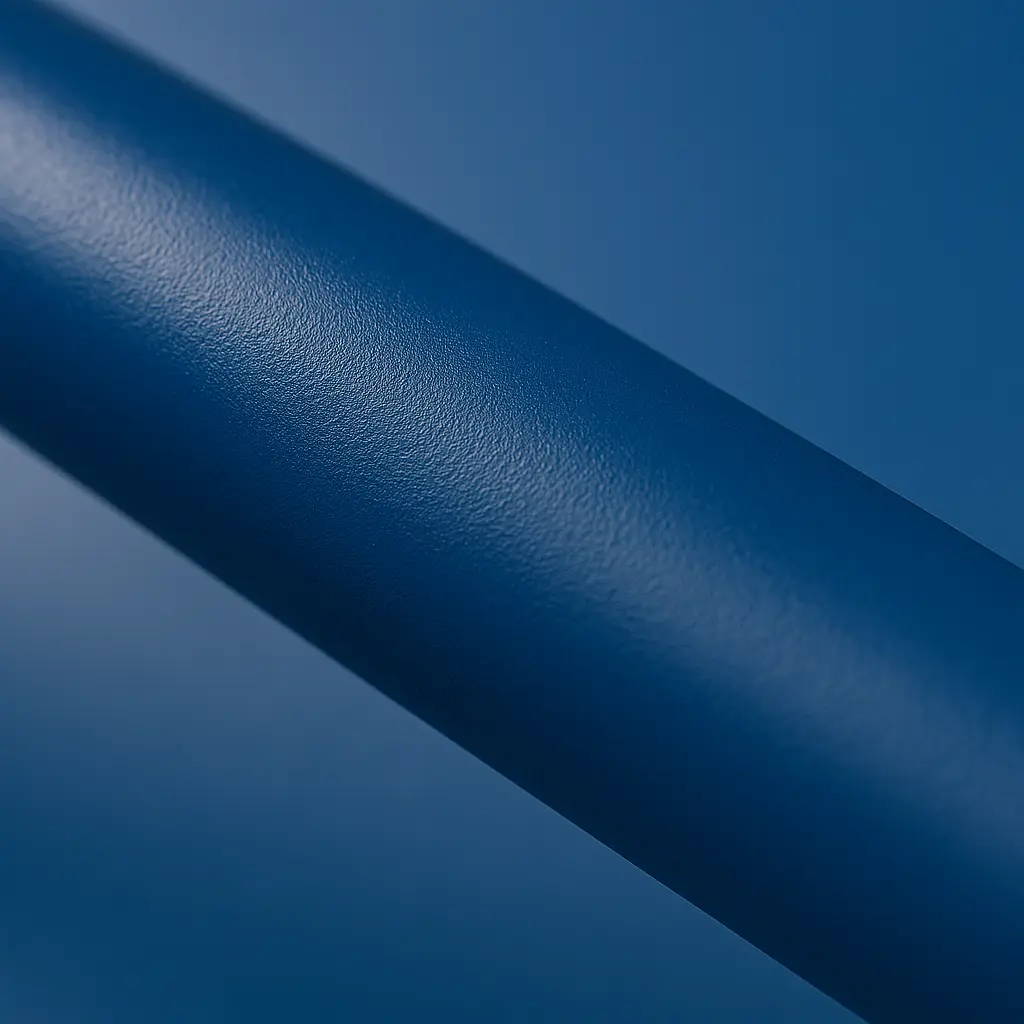

Powder Coating? Super Tough.

This is different. It’s like spraying on dry plastic powder. Uses static electricity to stick. Then you bake it in an oven. Melts into a hard, smooth shell. Really tough against scratches and chips. You see it on bike frames, patio chairs, appliances. Looks great. Downside? Need special gear – spray gun, big oven. Not a quick DIY fix if it gets chipped later.

Oil or Wax? Quick Fix.

Got hand tools? Garden shears? Machine parts you need to store? A thin coat of oil or wax works wonders. Pushes water away, blocks air for a while. Easy. But – it wears off! Gotta reapply it often, especially after you use the tool. Not for stuff left outside permanently.

Metal Plating? Fancy Coat.

Sometimes, they put a super-thin layer of another metal on top. Like chrome plating (think shiny car bumpers, less now though), or zinc plating (lots of nuts and bolts have this dull silver look). That layer protects the steel underneath. Zinc is extra clever – it actually rusts instead of the steel if it gets scratched (we’ll touch on that again). Plating? Done in factories, not at home.

Galvanizing? Zinc Armor!

This is a heavy-duty zinc coating. Usually done by dipping the whole steel part in melted zinc. Makes a thick, tough, grey coating (sometimes looks sparkly or mottled). Super good for outdoor stuff – fence posts, guardrails, metal roofing, outdoor bolts. Why? That zinc layer is a great barrier, and it sacrifices itself (rusts first) to protect the steel even if you scratch it. Really effective. Changes the look, though. Factory job too.

Smart Start: Pick the Right Metal

Maybe the easiest way? Don’t use metal that rusts easily if you don’t have to!

Use Stuff That Fights Back. Some metals are naturally good at resisting corrosion.

- Stainless Steel: The star player. Has chromium mixed in. Makes an invisible shield that fixes itself if scratched. Different types (grades) for different jobs. Kitchens, boats, hospitals – it’s everywhere for a reason.

- Aluminum: Light. Makes its own natural protective layer too. Doesn’t get red rust, but can get a white powdery corrosion in some conditions. Great for outdoor furniture, window frames.

- Copper, Brass, Bronze: No iron, so no ‘rust’. They do tarnish or corrode, often turning green (that’s the ‘patina’). That green layer actually protects the metal underneath. Used for pipes, decorations, boat bits.

- Why pick these? The protection is built right in! Less painting, less worry later maybe.

- But… They usually cost more than regular steel. And they have different strengths and weaknesses for building things.

Match Metal to the Mess. Think about where it’ll be used. Constant rain? Salty air by the sea? Chemicals nearby? Choose a metal known to handle that specific environment. Don’t use cheap steel where saltwater will hit it constantly.

Control the Wetness: Keep It Dry!

Rust needs water (or even just damp air) plus oxygen. If you can keep things dry, you slow rust way, way down.

Dry Storage is Your Friend. Keep metal tools, bikes, whatever, out of the rain and damp. Basements are often damp; maybe a dry garage or shed is better. Cover outdoor gear.

Suck Out Moisture. Got a damp workshop? A dehumidifier can help dry out the air.

Let Water Escape. Don’t let water pool on or around metal things. Make sure rainwater drains away properly.

Wipe Down Tools. Used your tools outside? Got them wet? Wipe ’em dry before putting them away. Simple but helps.

Watch Out for Nasty Stuff Too. Salt is brutal on metal. So are acids, some fertilizers, pool chemicals. If your metal stuff gets splashed with that, rinse it off with plain water quickly. Try not to store metal things near corrosive chemicals.

Taking the Hit: Sacrificial Protection

This is a neat science trick, used mostly in specific spots.

Let Something Else Rust First! You can attach a chunk of a different metal – one that corrodes more easily than steel, like zinc or magnesium – right onto the steel you want to protect. Especially useful underwater or buried underground. That ‘sacrificial’ metal chunk gets eaten away by corrosion first, saving the steel. Like a bodyguard taking the bullet. You see these zinc blocks on boat hulls, inside water heaters. They get used up over time, so you have to replace them eventually.

Design Smarter: Don’t Trap Water!

How something is designed can make it more or less likely to rust.

Avoid Puddles! If you’re designing something, think about where water might sit. Avoid little crevices, flat spots with no drainage, or gaps where moisture can get trapped and stay. Angled surfaces and drain holes are good things!

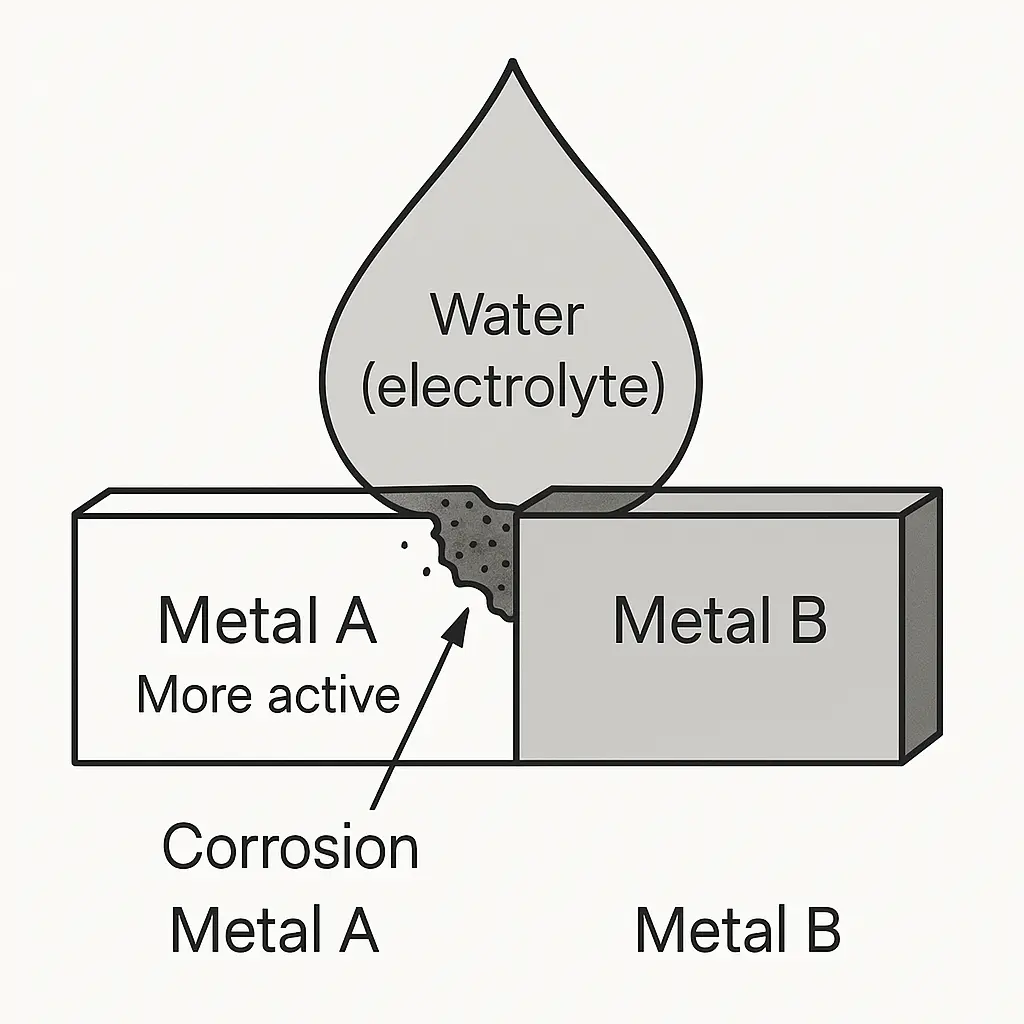

Mixing Metals? Be Careful! If you bolt two different kinds of metal together (like copper touching steel) and they get wet, you can actually make one of them corrode faster. It’s like a tiny battery. Called galvanic corrosion. Best to avoid joining very different metals in wet spots if you can. Or, use plastic washers or gaskets to keep them separated.

Keep It Clean: Simple Works Too

Don’t forget the easy stuff. Just washing metal things regularly gets rid of dirt and salts that hold moisture against the surface. If you have paint or oil on something, cleaning lets you see if the coating is damaged so you can fix it before rust starts underneath.

So, What’s the Plan? Fight Rust Many Ways!

There’s no single magic fix for rust. Usually, the best bet is using a mix of these ideas. Maybe you buy something made of galvanized steel, then you paint it too, and you try to keep it clean and dry. From picking the right metal, to coating it well, to just wiping down your tools – you’ve got options. Knowing them helps you keep your metal stuff looking good and working right for much longer.