Stainless steel doesn’t rust easily because it has chromium. Carbon steel is strong and cheaper but needs paint or coating to stop rust. Choose stainless for looks/wet areas, carbon for strength/budget.

Key Takeaways

- Stopping Rust: Stainless has a built-in chromium shield. Carbon steel rusts bare; needs cover like paint/oil.

- What’s Inside: Stainless = Iron + Chromium (10.5%+). Carbon = Iron + Carbon (the key extra).

- The Cost Factor: Carbon steel usually costs much less than stainless.

- How They Look: Stainless often stays shiny/brushed. Carbon steel looks duller, gets coated.

- Where They’re Used: Stainless suits wet/clean spots. Carbon is for strong structures/tools.

Table of Contents

Introduction

Lots of things are made of steel, but “steel” can mean different things. Two big ones are stainless steel and carbon steel, and they behave differently. Knowing the contrasts between stainless steel and carbon steel helps you pick the smart choice for your needs, factoring in how long it must last, how it should look, and what you can spend.

What is Stainless Steel? (Brief Overview)

What makes stainless steel special? As an iron alloy, its real talent lies in shaking off rust and corrosion. This defense mechanism works because it contains at least 10.5% chromium, creating an invisible, self-healing shield on its surface. People value it for its long life and clean appearance. For a deeper look into stainless steel types and their wide range of uses, our detailed guide is right here.

What is Carbon Steel?

Think of carbon steel as iron mixed mainly with carbon. It doesn’t have that high dose of chromium like stainless steel does. This is why it’s strong and hard, but also why it rusts if you leave it out in the damp air. How much carbon is added really changes how it acts:

- Low-Carbon Steel (Mild Steel): With just a small amount of carbon (around 0.05-0.25%), this is the kind you see most often. It bends without much fuss and takes welding well, making it a favorite for building structures or car bodywork.

- Medium-Carbon Steel: Upping the carbon content (about 0.25-0.60%) gives you steel that’s tougher and more resistant to wear, but it’s also a bit less forgiving when you try to shape it. Axles and gears often use this type.

- High-Carbon Steel: Packing a good amount of carbon (0.60-1.25%), this stuff gets very hard and can hold a killer edge, although it might snap more easily than bend. It’s the choice for cutting tools or strong springs.

Since carbon steel is quite vulnerable to rusting if left bare, it’s standard practice to give it some defense – often paint or a layer of zinc through galvanizing – so it holds up over the long haul.

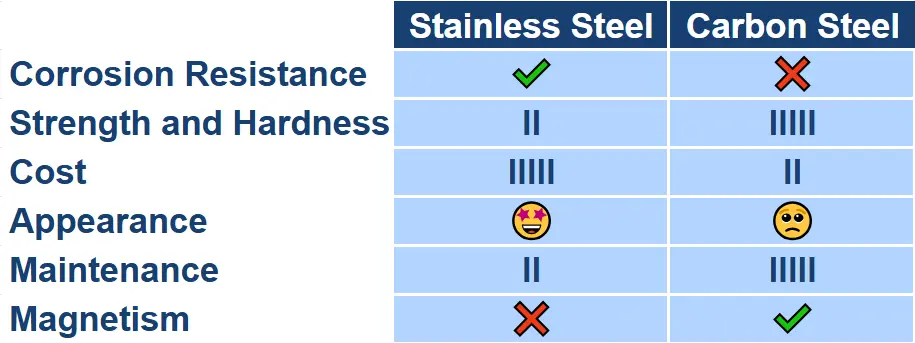

Stainless Steel vs Carbon Steel: Direct Comparison

Let’s put these materials head-to-head on the important stuff:

Corrosion Resistance

- Stainless Steel: Does exceptionally well here. That chromium oxide layer works wonders. While some grades resist corrosion better than others, the basic ability is baked in.

- Carbon Steel: Doesn’t stand much chance on its own. It absolutely needs a protective layer (paint, plating, oil) to fend off rust.

Strength and Hardness

- Stainless Steel: Offers respectable strength for many jobs. Certain types (martensitic) can be heat-treated to get very hard. Others (austenitic, the common stuff) are tough but don’t harden much with heat, instead getting stronger if you bend or shape them.

- Carbon Steel: Can reach very high levels of hardness and strength, particularly the medium and high-carbon varieties when properly heat-treated. It’s frequently picked when getting the absolute maximum hardness is the goal.

Cost Comparison

- Stainless Steel: You’ll typically find this metal costs more. Having extra elements like chromium and nickel included drives up the production expense.

- Carbon Steel: Definitely the more economical choice. Being made from simpler, widely available materials keeps its price down.

Appearance

- Stainless Steel: Provides different visual options, from a highly polished gleam to a softer brushed effect. It keeps its looks without needing paint.

- Carbon Steel: In its raw state, it’s typically a dull, flat grey. It depends on coatings like paint for both its appearance and its protection.

Workability and Machinability

- Stainless Steel: Working with this metal is certainly possible, though some grades might present challenges or demand specific techniques, particularly when machining types prone to hardening during cutting.

- Carbon Steel: Many find this material less troublesome to work with overall. Mild steel, especially, is well-regarded for being agreeable when it comes to cutting, welding, and bending. As carbon increases, it gets tougher to work.

Weight

- Stainless Steel: Its density is generally somewhere between 7.7 and 8.0 g/cm³.

- Carbon Steel: Usually lands around 7.85 g/cm³.

For almost all situations, the weight difference between them is too small to matter.

Maintenance Requirements

- Stainless Steel: Needs very little upkeep related to corrosion. Cleaning is usually just for looks.

- Carbon Steel: Demands more attention. Protective coatings need monitoring and occasional touch-ups or renewal to prevent rust.

Magnetic Properties

- Stainless Steel: It varies. Common austenitic types (304, 316) aren’t magnetic. Ferritic and martensitic types are.

- Carbon Steel: Is magnetic. It will readily stick to a magnet.

Common Applications

Where do these materials typically end up? Their properties guide their use:

Typical Stainless Steel Uses

Favored where rust is a major concern or hygiene is paramount:

- Kitchen sinks, cookware, utensils

- Surgical tools, medical implants

- Equipment for food and beverage industries

- Building facades, railings

- Parts exposed to marine environments

Typical Carbon Steel Uses

Chosen for strength, hardness, and cost, where rust can be addressed:

- Construction: Building frames (beams, columns), concrete reinforcing bars

- Automotive: Vehicle chassis, bodywork, engine components

- Pipelines: Transporting resources like oil and gas (with protective lining/coating)

- Tools: Various hand tools; cutting edges often use high-carbon variants

- Machinery: Heavy equipment frames, gears, durable parts

- Cookware: Items like woks or cast-iron skillets valued for heat handling (need seasoning)

- Hardware: Everyday nuts, bolts, plates

Which Steel to Choose?

Your decision should balance these factors:

- Must Avoid Rust? Go with Stainless Steel.

- Tight Budget? Carbon Steel is more economical.

- Need Extreme Hardness? Heat-treated High-Carbon Steel is a strong contender.

- Want Uncoated Good Looks? Stainless Steel delivers.

- Prefer Low Maintenance? Stainless Steel wins on corrosion.

- Magnetism Matter? Carbon Steel is reliably magnetic; Stainless Steel depends on the grade.

Conclusion: Choosing the Right Steel

Ultimately, the stainless steel vs carbon steel decision comes down to the specific demands of the job. Stainless provides built-in rust defense and a lasting finish, justifying its cost where those features are vital. Carbon steel offers robust strength and affordability, making it the go-to for countless applications where its tendency to rust can be effectively managed. Weighing resistance, strength, cost, and upkeep will guide you to the best steel choice.