Iron is a natural, brittle element. Steel is an engineered alloy of iron and carbon, making it far stronger, more durable, and versatile for modern construction and manufacturing.

Key Takeaways

- Iron is an element; Steel is an alloy. This is the most fundamental difference.

- Carbon is the key. Steel’s superior strength and durability come from adding a small, controlled amount of carbon to iron.

- Steel is stronger and more versatile. Unlike brittle cast iron, steel has high tensile strength, meaning it can bend before breaking, making it suitable for construction.

- Steel can be rust-proof. While both rust, steel can be alloyed with chromium to create stainless steel, which is highly corrosion-resistant.

- Production differs. Iron is smelted from ore, while steel is refined from iron by reducing its carbon content.

Table of Contents

The two materials are fundamentally linked but vastly different in their properties and uses. Here is an in-depth explanation of the difference between iron and steel.

The Core Difference: Element vs. Alloy

The simplest way to understand the difference is this:

- Iron (Fe) is a chemical element. It is a metal that occurs naturally in the Earth’s crust, primarily as iron ore. In its pure form, it is relatively soft and not very useful for construction or manufacturing.

- Steel is an alloy. It is not a pure element. It is primarily made of iron, but with a small, controlled amount of carbon added to it. It’s this addition of carbon that transforms the soft, brittle iron into one of the most versatile and durable materials in the world.

Think of it like this: Iron is the primary ingredient, and steel is the finished recipe.

In-Depth Breakdown

Let’s explore the differences across several key areas.

01. Composition

Iron:

The term “iron” can refer to a few things.

- Pure Iron (Fe): An element on the periodic table. It is rarely used commercially in this form.

- Pig Iron: The raw, impure iron tapped from a blast furnace. It has a very high carbon content (3.5% – 4.5%), making it very brittle.

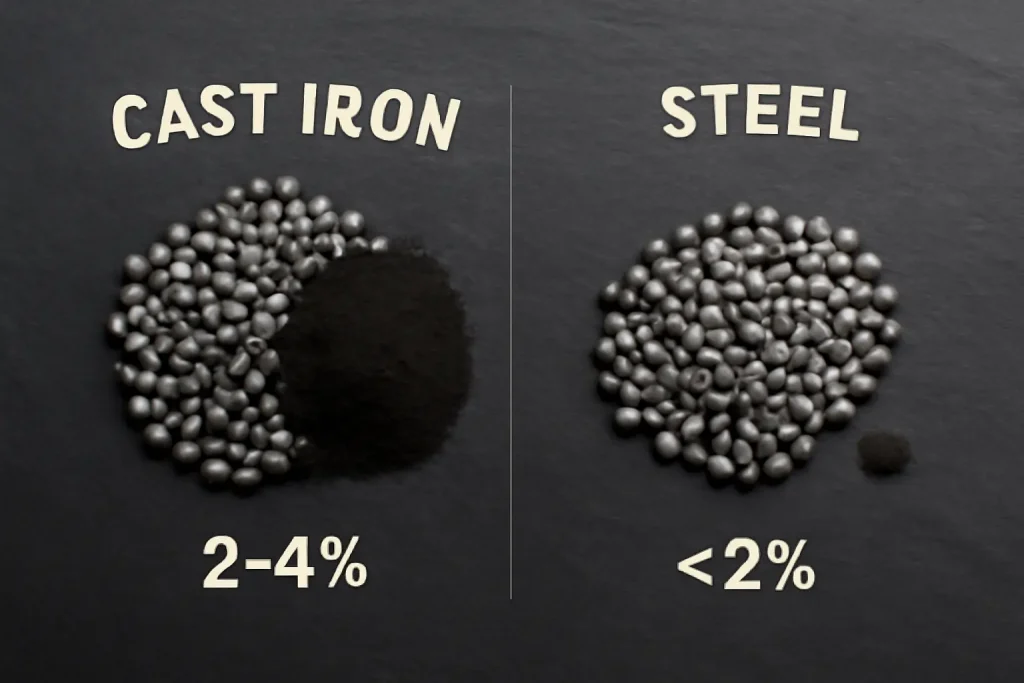

- Cast Iron: Made by re-melting pig iron. It still has a high carbon content (2% – 4%) and is strong under compression but brittle under tension (it will crack rather than bend).

Steel:

An alloy of iron and carbon, where the carbon content is deliberately managed to be much lower, typically between 0.02% and 2.1% by weight.

- This small amount of carbon is the magic ingredient. It makes steel significantly stronger, harder, and more durable than iron.

- Steel can also contain other elements (like manganese, chromium, nickel, etc.) to give it specific properties, creating thousands of different types of steel.

02. Atomic Structure and Properties

This is the scientific heart of the difference.

In Pure Iron:

The iron atoms are arranged in a regular crystal lattice. When a force is applied, these layers of atoms can slide over one another relatively easily. This makes pure iron malleable (can be hammered into shape) but also relatively weak.

In Steel:

The carbon atoms are much smaller than the iron atoms. They fit into the gaps between the iron atoms in the crystal lattice. This acts like a “locking” mechanism. The carbon atoms disrupt the neat layers, making it much harder for the layers of iron atoms to slide past each other.

This atomic-level “locking” results in:

- Increased Strength: Steel has much higher tensile strength (ability to be pulled apart without breaking) than iron. Cast iron is strong in compression (being squeezed) but will snap under tension. Steel is strong in both.

- Increased Hardness: Steel is significantly harder than iron and can hold a sharp edge.

- Reduced Brittleness (Increased Ductility): By controlling the carbon content, steel can be made to bend before it breaks (ductility), whereas high-carbon cast iron is brittle and will shatter.

03. Production Process

Iron (Pig Iron/Cast Iron):

Iron ore is heated in a blast furnace with coke (a high-carbon fuel) and limestone. The coke provides the heat and carbon, and the limestone removes impurities. The molten, high-carbon material that comes out is pig iron. This pig iron can then be cast into molds to create cast iron products.

Steel:

Steel production is a refinement process. It starts with either molten pig iron or scrap steel. The goal is to reduce the carbon content to the desired level and remove impurities like sulfur and phosphorus. This is typically done in a Basic Oxygen Furnace (BOF) or an Electric Arc Furnace (EAF). After the carbon is lowered, other alloying elements can be precisely added.

04. Corrosion (Rusting)

Iron:

Both pure iron and cast iron are highly susceptible to rust (iron oxide) when exposed to oxygen and moisture. The rust layer is flaky and falls off, exposing fresh metal underneath to continue rusting.

Steel:

Carbon Steel (the most common type) also rusts easily, often at a similar rate to iron. However, steel can be made highly corrosion-resistant by adding other elements. The most famous example is Stainless Steel, which is an alloy of iron, carbon, and at least 10.5% chromium. The chromium forms a passive, invisible layer of chromium oxide on the surface that prevents rust from forming.

Comparison Table: Iron vs. Steel at a Glance

| Feature | Iron (Specifically Cast Iron) | Steel |

| Nature | Element-based material (high carbon) | An engineered alloy of iron and carbon |

| Composition | Iron + high Carbon content (2% – 4%) | Iron + controlled Carbon content (0.02% – 2.1%) |

| Tensile Strength | Low (brittle) | High to Very High |

| Compressive Strength | High | High |

| Hardness | Hard but brittle | Can be engineered to be extremely hard and tough |

| Ductility | Very low (will crack, not bend) | Varies from low to very high depending on type |

| Corrosion | Rusts very easily | Also rusts, but can be made corrosion-proof (e.g., Stainless Steel) |

| Production | Smelted from ore into pig iron | Refined from pig iron or scrap steel |

| Applications | Engine blocks, skillets, pipes, decorative railings | Skyscrapers, cars, ships, knives, tools, appliances, medical implants |

| Versatility | Limited | Extremely versatile; thousands of different grades exist |

Analogy: Building with Bricks

- Imagine Iron atoms are like perfectly smooth, identical Lego bricks. You can stack them high, and they are strong against being pushed down (compression), but if you pull on the structure from the side (tension), the layers of bricks slide apart easily.

- Now, imagine Steel. The Carbon atoms are like tiny, rough grains of sand that you sprinkle between the layers of Lego bricks. This sand gets into the gaps and creates friction, making it much harder for the layers of bricks to slide apart. The structure is now strong in all directions.

- Alloy Steels (like Stainless Steel) are like adding special-purpose Lego pieces (like ones with hinges or different shapes) to give your structure new capabilities, like being waterproof (rustproof).

Conclusion

Iron is the raw, fundamental building block, while steel is the sophisticated, engineered material derived from it. The simple act of controlling the carbon content and adding other elements unlocks a universe of properties that makes steel the foundation of the modern world, used in everything from paper clips to suspension bridges.