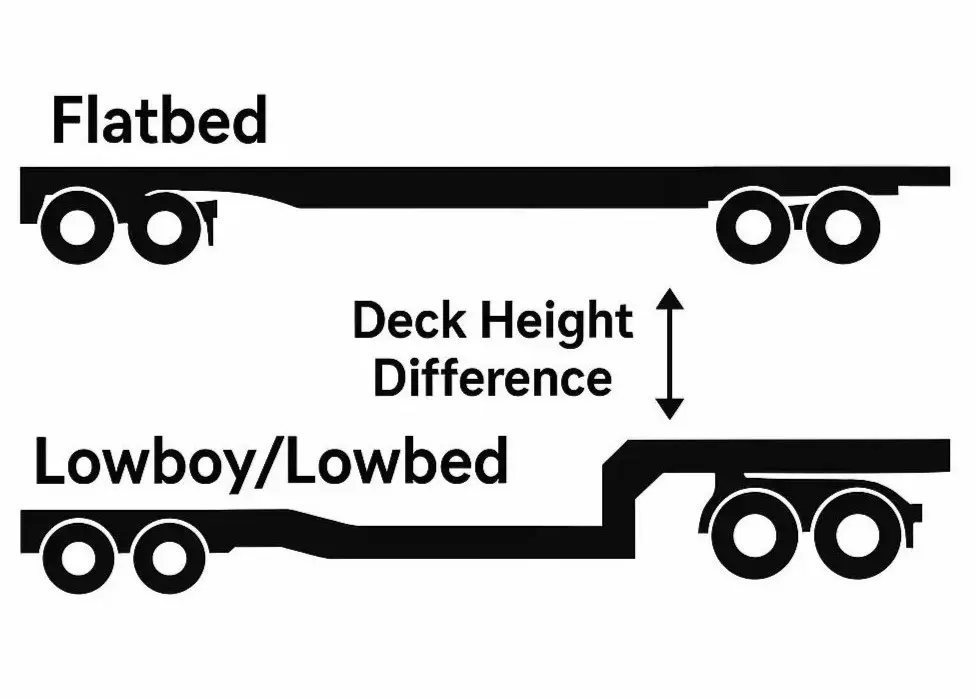

The key difference? Flatbeds have a completely flat deck. Lowboy/Lowbed trailers have a main deck section that drops much lower, mainly designed for carrying really tall cargo safely.

Key Takeaways

- Deck’s the Difference: Flatbeds? One level deck. Lowboys/Lowbeds? Sunken middle deck.

- Flatbed Jobs: Good all-rounders for stuff that’s not too high – building supplies, some machines, pipes. Easy to load from sides.

- Lowboy/Lowbed Jobs: Built specifically for extra tall things – big diggers, huge factory parts – so they fit under bridges.

- The Names: “Lowboy” = mostly US/Canada. “Lowbed” = other places, often means the same low-deck idea.

- Loading Them: Flatbeds are easy. Lowboys often need ramps or the front neck part comes off (RGN) to drive equipment on.

Table of Contents

Introduction

See those big rigs rolling down the highway? Lots of different trailers behind them. You’ve probably noticed the plain flat ones, just an open bed. And then there are those other ones, the really low-slung trailers, often hauling giant yellow construction machines. They might both look like open platforms, but that super low trailer – the Lowboy or Lowbed – is built very differently from a standard Flatbed. Knowing how they’re different matters a lot if you’re in trucking, moving heavy stuff, or even just wondering about those massive loads you see passing by. Let’s check out what makes each one unique.

What is a Flatbed Trailer?

Think basic. Think useful for lots of things. A Flatbed trailer is pretty much what it sounds like – just a flat, open deck. No roof, no walls, maybe just some low rails or places to stick stakes around the edge.

- How it Looks: Just a straightforward platform on wheels. The floor stays at the same height all the way along, usually about waist-high or maybe a bit higher (around 4-5 feet / 1.2-1.5 meters), kind of like a loading dock.

- Getting Stuff On/Off: Super flexible. Since it’s open, forklifts can load from the sides easily. Cranes can drop stuff on from above. You can load from the back too.

- What it Carries: Because they’re so simple, flatbeds haul all sorts of things, as long as it’s not too tall and doesn’t need protection from rain or wind (unless tarped). Think:

- Building supplies – stacks of lumber, long steel beams, big pipes.

- Machines or equipment (if they’re not higher than road limits).

- Stuff on pallets or in bags (if tied down well).

- Even cars sometimes.

- Tying it Down: No sides means you have to secure the load really well. Lots of straps, chains, maybe heavy tarps to cover things up. That’s crucial.

What is a Lowboy / Lowbed Trailer?

Now picture a trailer with a serious dip in the middle. The main floor sits way lower than on a flatbed. That’s a Lowboy or Lowbed trailer.

- How it Looks: It’s got a kind of step-down design:

- There’s a raised part at the front (the ‘gooseneck‘) that hooks onto the truck.

- Then, the main deck drops down really low, much closer to the road (maybe only knee-high or waist-high off the ground – like 1.5-2.5 feet / 0.5-0.75 meters). This low part is where the big cargo goes.

- At the very back, the deck usually comes back up a bit over the wheels.

- Why So Low? That super low main deck is the key. It lets truckers haul really tall stuff – think big construction machines, factory equipment, even parts of houses – without hitting bridges or power lines. It keeps the overall height of the truck + trailer + cargo within the legal road limits.

- Getting Stuff On/Off: Loading huge, heavy equipment onto that low deck needs special tricks:

- RGN (Removable Gooseneck): This is common on Lowboys. The whole front gooseneck part can actually detach and pull away. The front of the low deck then acts like a ramp, so equipment can just be driven straight on from the ground. Super handy for big tracked machines like excavators.

- Ramps: Some fixed-neck Lowbeds use ramps, often attached at the back, to let equipment drive up over the rear axles onto the low deck.

- What it Carries: Mostly the big, awkward, TALL stuff:

- Heavy construction gear (diggers, bulldozers, road pavers).

- Big farm equipment (tractors, combines).

- Oversized factory parts (tanks, generators).

- Anything else too tall or heavy for a standard flatbed.

Lowboy or Lowbed – What’s the Deal with the Name?

You’ll hear both names, Lowboy and Lowbed. Do they mean different things? Mostly, no. People often use them to mean the same thing: a trailer with that dropped deck for tall loads.

- In the US and Canada, you’ll probably hear “Lowboy” more often. It usually implies that specific drop-deck design, often with the RGN feature.

- In other places like the UK or Europe, “Lowbed” might be more common, or used as a general term for any low-deck trailer. Some might say there are tiny technical differences, but honestly, if someone’s talking about hauling a big excavator, they mean the same type of trailer whether they call it a Lowboy or a Lowbed.

So, don’t get too hung up on the name. Both point to that low-deck design for handling tall cargo. We’ll just say “Lowboy/Lowbed” here to cover the bases.

Spot the Difference: Flatbed vs. Lowboy/Lowbed Trailer

Let’s quickly sum up the main things that set them apart:

| Feature | Flatbed Trailer | Lowboy / Lowbed Trailer |

| Deck Shape | Totally Flat, One Level | Drops Low in the Middle (‘Well’) |

| Deck Height | Higher (4-5 ft approx) | Main Deck Much Lower (1.5-2.5 ft approx) |

| Main Job | General Hauling (Not Too Tall) | Hauling Very Tall & Heavy Stuff |

| Loading | Easy from Sides/Top/Rear | Needs Ramps or Removable Neck (RGN) |

| Built For | Variety of Loads | Heavy, Concentrated Loads (Equipment) |

| Design | Simpler | More Complex Structure |

| Cost | Generally Less Expensive | Generally More Expensive |

When to Use Which One?

It really depends on what needs hauling:

- Got lumber, pipes, steel beams, maybe some machinery that isn’t super tall? Flatbed is your go-to. Versatile, easy to load, gets the job done for lots of standard stuff.

- Got a huge excavator, a massive bulldozer, a giant factory tank, or anything else that would be way too high on a regular trailer? You need a Lowboy/Lowbed. That low deck is specifically made to handle that height safely and legally.

Conclusion: Different Tools for Different Loads

So, while they might both be open trailers, flatbeds and Lowboy/Lowbeds are built for different worlds of hauling. The flatbed is your flexible friend for all sorts of regular cargo. The Lowboy/Lowbed is the specialized problem-solver, using its unique low-deck design to make moving the tallest, heaviest equipment possible on our roads. Knowing which is which helps understand how all that big stuff gets moved around!