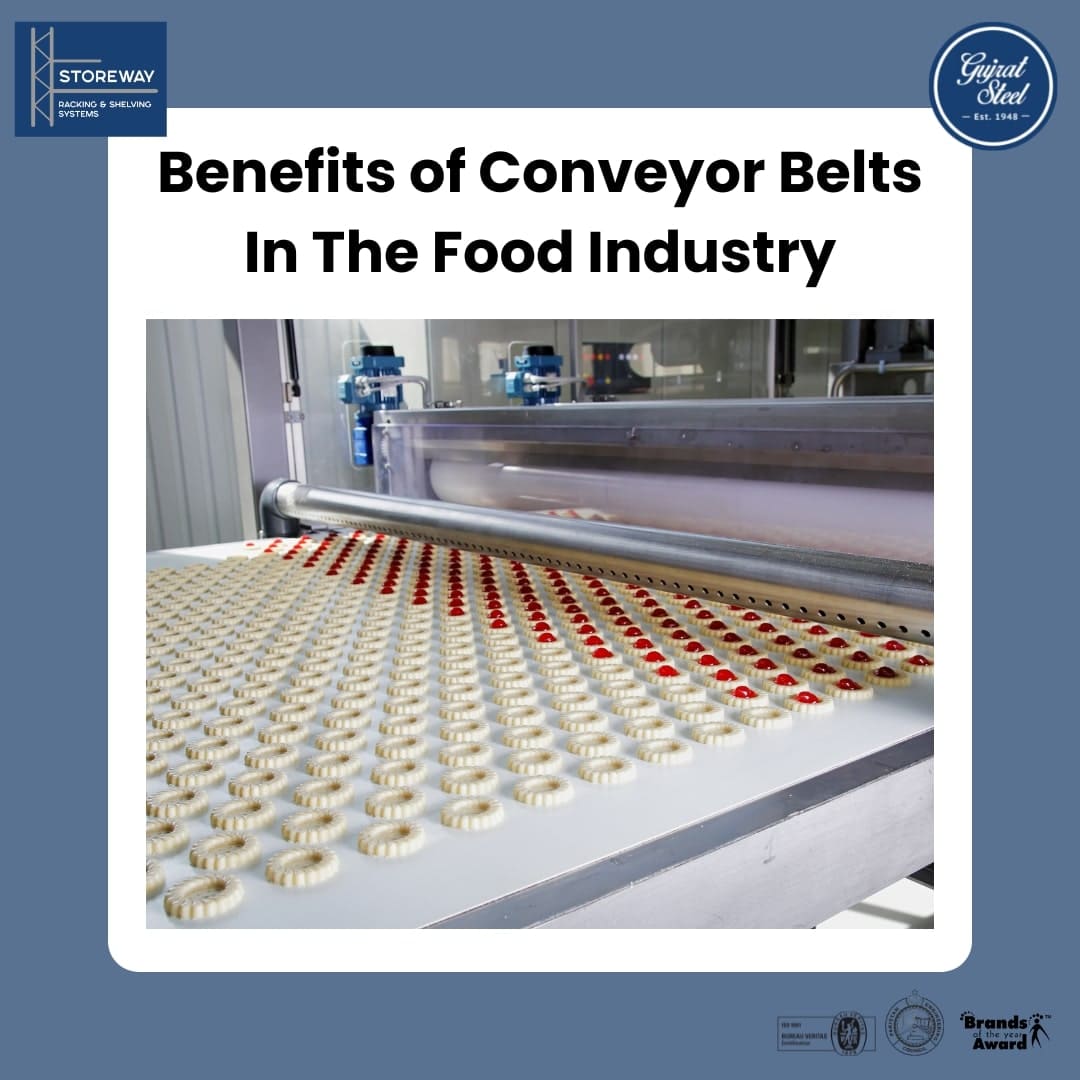

As food production became more industrialized, manufacturers quickly realized the advantages of belt conveyor systems. Operations no longer needed to wait on workers to move heavy loads to different factory locations, creating important production efficiencies. The introduction of the food conveyor belt also helped the food industry meet increasing state and federal regulations — conditions became more sanitary as food was handled less.

Advantages of Using Conveyor Belts in a Food Industry

- They Minimize Manual Labor:

A fair amount of the food industry deals with handling and processing bulk materials. Conveyor Belts can help minimize the level of manual labor involved. They can even potentially eliminate manual labor altogether.

Before Conveyor Belts were commonplace in the food industry, the process of transporting foodstuffs was slow, energy-intensive, and ineffective. In many industries, the old adage that ‘time is money’ still applies. The food industry is no different. By relying strictly on manual labor, many food businesses run the risk of losing out on productivity. This then turns into financial losses.

The introduction of a Conveyor Belt can reduce employment costs and cut down on overall training time. Moreover, it increases the level of automation that is possible in a facility. Automation is particularly appealing to many businesses. This is because a Conveyor Belt can transport raw materials to a processing area. Then it can also transport packaged goods that are ready for shipment.

- Conveyor Belts Reduce Accidents:

Between the pulleys, idlers, rollers, and tensioners, mechanical devices have plenty of moving parts. Luckily, with Conveyor Belts, employees seldom have to interact with them and employees therefore have less risk because they’re not carrying heavy loads.

Also, modern Conveyor Belts carry less risk for mechanical failure and injury. Additionally, due to increases in labor efficiency, you’ll have less staff manning the facility floor at any given time. Therefore, there are fewer employees to oversee and monitor.

Furthermore, employees are most liable to be positioned at the side of the Conveyor Belt. Then, they won’t have to directly interact with any of its moving parts unless they must make specific repairs. This is a great way to minimize workplace hazards.

- Conveyor Belts Increase Food Safety and Quality:

When it comes to your food, you probably want products that haven’t been directly handled very much. Especially since many modern grocery products come from factories and facilities, Conveyor Belts can help improve overall food safety.

Many newer Conveyor Belts keep products and foodstuffs free of contaminants by design. For food and beverages, it’s important to keep products dust-free and contamination-free before they go to their final destination.

Ensuring that a facility is clean and free of potential contaminants is a big aspect of Pakistan Food Authority compliance. When a facility violates the governmental regulations they can face fines, legal consequences, and business closures. But with the advancements in Conveyor Belt technology, most facilities find it easier to remain in compliance.

Why Choose Gujrat Steel’s Conveyor Belts?

Looking for a conveyor? Well Gujrat Steel has exactly what you want. Our steel conveyors are used in a wide variety of industrial applications and are particularly suited to hygiene conscious environments.

Our steel conveyors are simple, easy to clean and efficient. We can work with you to help you design and install the best materials handling solution to suit your business requirements.

Since conveyors make the transportation of business materials and products quick and efficient, they will be extremely useful in your material handling, warehouse, logistics, food and beverage production, packaging, distribution, inspection or manufacturing facilities or assembly shops.

At present, we are offering two conveyor options to our clients:

- Roller Conveyors

- Belt Conveyors