Warehouse racking safety is a comprehensive system of procedures, inspections, and best practices designed to prevent rack collapses and accidents. It involves correct installation, rigorous operator training, regular damage audits, and the use of protective equipment to ensure the structural integrity of your storage systems and protect your personnel.

Key Takeaways

- Proactive Inspections are Key: Regular, documented inspections are the single most effective way to identify and address potential racking hazards before they lead to catastrophic failure.

- Damage is Inevitable; Ignoring It is a Choice: Even minor-looking damage to a rack upright can reduce its load capacity significantly. A clear “report, assess, and repair” policy is mandatory.

- Training is Your First Line of Defense: A well-trained forklift operator who understands loading protocols and the importance of warehouse racking safety is your best asset in preventing accidents.

- Load Capacity is a Limit, Not a Suggestion: Every racking system has a clearly defined maximum load capacity. Overloading is a primary cause of rack collapses and must be strictly prohibited.

Table of Contents

The Pillars of Effective Warehouse Racking Safety

A safe warehouse doesn’t happen by accident. It is the result of a deliberate and sustained commitment to creating a culture of safety. For facilities that rely on pallet racking, this culture is built upon a deep understanding of the forces at play and the risks involved. Effective warehouse racking safety isn’t just about avoiding fines from regulators; it’s about protecting your most valuable assets: your people and your inventory.

This guide will walk you through the essential components of a world-class safety program, from initial installation to daily operational procedures and long-term maintenance. Implementing these strategies will not only prevent disasters but will also improve efficiency and reduce costly damage to products and equipment.

Foundation First: Correct Installation and Design

You cannot build a safe system on a faulty foundation. The very first step in ensuring long-term warehouse racking safety begins with the professional design and installation of the system itself.

Understanding Load Capacity and Specifications

Every single beam and upright in your racking system is engineered to hold a specific maximum weight. This information, often displayed as Load Application and Rack Configuration (LARC) drawings, should be clearly posted and easily visible to all warehouse staff.

Overloading a beam, even temporarily, can cause it to deflect or permanently deform. Overloading an entire bay can compromise the integrity of the upright frames, leading to a domino-effect collapse. Strict adherence to posted load capacities is a non-negotiable rule.

The Importance of Professional Assembly

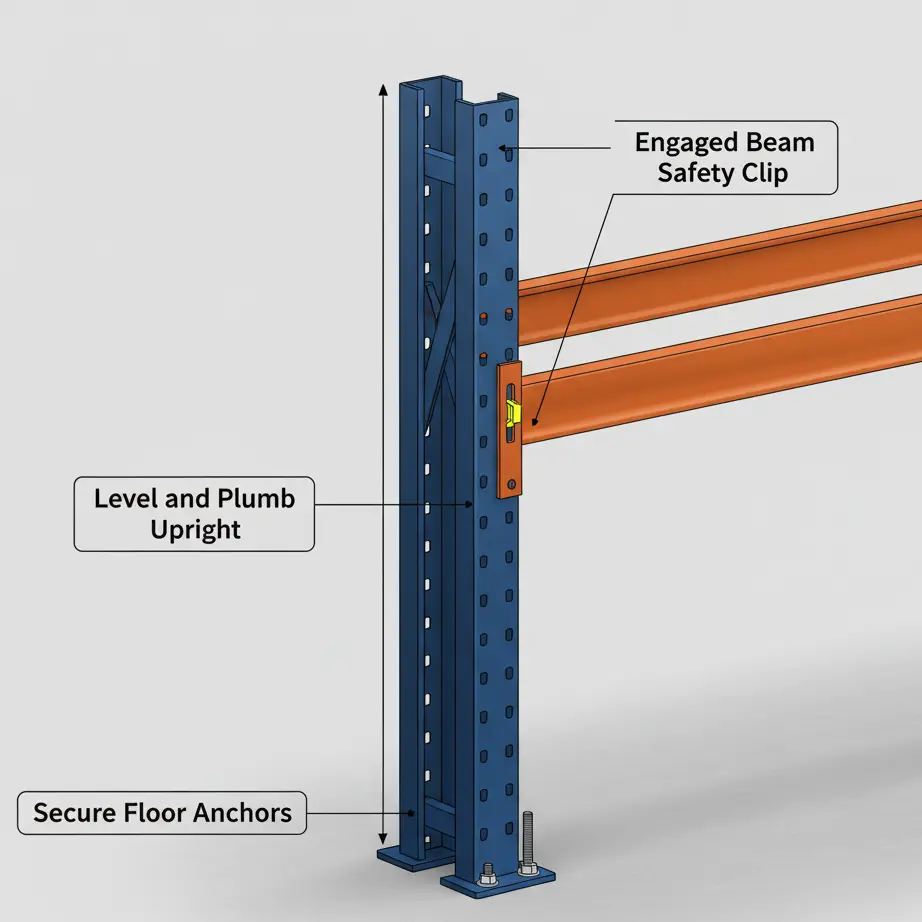

Pallet racking may look like a simple set of components, but its assembly requires precision. Beams must be correctly seated and safety clips properly engaged. Uprights must be plumb, level, and securely anchored to a suitable concrete floor.

Using a professional and certified installation team ensures that the system is assembled exactly as the manufacturer intended. This guarantees that it will perform to its stated specifications and is the first critical step in your overall warehouse racking safety program. Any modifications or reconfigurations of the racking in the future should also be handled by qualified professionals.

The Human Element: Operator Training and Safe Practices

The vast majority of racking damage is caused by impacts from material handling equipment, most commonly forklifts. Therefore, thorough and ongoing operator training is a cornerstone of any successful safety initiative.

The Critical Role of Operator Training in Warehouse Racking Safety

A driver’s license does not qualify someone to operate a forklift in a crowded warehouse. Operators must receive formal training and certification on the specific equipment they will be using. This training must go beyond basic operation and cover:

- Proper Loading and Unloading Techniques: This includes approaching the rack squarely, lifting to the correct height, and placing the pallet gently and centrally onto the beams. Dragging or pushing pallets on the beams should be forbidden.

- Awareness of Speed and Turning Radius: Operators must understand the importance of maintaining safe speeds, especially around corners and at the end of aisles where impacts are most common.

- Understanding Aisle and Flue Space: They need to be trained on maintaining clear transverse and longitudinal flue spaces for fire safety compliance.

- Immediate Damage Reporting: Every operator must be empowered and required to report any and all impacts to the racking, no matter how minor they may seem. There should be no penalty for reporting an accidental impact.

Your Guide to Proactive Warehouse Racking Safety Inspections

You can’t fix a problem you don’t know exists. A regular and systematic inspection process is the only way to catch damage early and maintain consistent warehouse racking safety. These inspections should be performed at different intervals and levels of detail.

Daily Informal Checks

Forklift operators and other on-the-ground staff should be trained to be the eyes and ears of the safety program. They should be encouraged to visually scan the racking in their work area at the start of every shift and report any visible damage, misplaced pallets, or potential hazards immediately.

Weekly or Monthly Internal Audits

A designated supervisor or safety manager should conduct a more formal walkthrough on a weekly or monthly basis. This person should be equipped with a checklist and actively look for common types of damage.

A Basic Warehouse Racking Safety Checklist:

- Uprights: Check for dents, scrapes, twists, or buckling. Pay special attention to the front and rear posts at the bottom 1-2 meters, where impacts are most frequent.

- Beams: Look for sagging or deflected beams. Check the beam connectors for any deformation and ensure the safety clips are present and properly engaged.

- Bracing: Inspect the horizontal and diagonal frame braces for any signs of bending or damage from impacts.

- Anchors: Verify that all base plates are securely anchored to the floor and that there are no loose or sheared anchor bolts.

- Load Labels: Ensure that load capacity labels are present, legible, and accurate for the current rack configuration.

Annual Expert Inspections

At least once a year, it is highly recommended to have a third-party, qualified rack safety expert or engineer conduct a comprehensive inspection of your entire system. They have the expertise to spot subtle signs of stress or fatigue that an internal team might miss and can provide certified guidance on necessary repairs or replacements.

Identifying and Managing Rack Damage

Recognizing damage is the first step. Knowing how to classify and manage it is what keeps your operation safe.

The “Traffic Light” System for Damage Assessment

A simple and effective way to manage reported damage is to use a color-coded system:

- Green (Observation): This is for very minor scrapes or surface-level damage that does not appear to affect the structural integrity of the component. The area should be noted and re-inspected during the next audit.

- Amber (Hazard – Unload and Monitor): This level of damage requires immediate attention. This includes noticeable dents in an upright or slight deformation in a beam. The affected bays should be immediately offloaded and clearly marked as out-of-service. A qualified person must then assess whether a repair or replacement is needed.

- Red (Immediate Danger – Isolate and Unload): This is for severe damage, such as a badly buckled upright, a sheared anchor, or a significantly deflected beam. The entire area must be cordoned off immediately to all traffic. Unloading of the affected bays should only be done after a careful risk assessment, as the rack is in a dangerous state.

Investing in Prevention: Rack Protection Accessories

While training and inspections are crucial, physical protection can significantly reduce the frequency and severity of rack damage. Investing in warehouse racking safety equipment is far less expensive than dealing with the aftermath of a collapse.

Column Guards and End-of-Aisle Protectors

These are heavy-duty steel guards that are anchored to the floor in front of or around the base of the rack uprights. They act as a sacrificial barrier, absorbing the force of a forklift impact and protecting the critical vertical column from damage. End-of-aisle protectors are especially important as this is the most vulnerable location in the entire system.

Pallet Backstops and Safety Netting

Pallet backstops are simple beams or bars that are installed at the back of a rack bay to prevent operators from accidentally pushing a pallet too far back, which can cause it to fall into the flue space or onto a workspace behind the rack. Safety netting can be installed on the back of racks to catch any dislodged items or full pallets, protecting personnel in pedestrian walkways below.

Conclusion

Warehouse racking safety is not a project with a finish line; it is an ongoing commitment to vigilance. By combining professional design, comprehensive training, a rigorous inspection schedule, and smart investments in protection, you create a resilient system that protects your people, safeguards your inventory, and supports a productive, efficient operation.