Warehouse optimization is the systematic process of enhancing the efficiency, productivity, and accuracy of warehouse operations. The primary objective is to minimize costs, maximize throughput, and elevate the customer experience through a combination of improved warehouse layout design, technology integration, process reengineering, and employee training. For businesses, particularly in the e-commerce sector, this means streamlining receiving, picking, packing, shipping, and returns to process orders in the most rapid and cost-effective manner possible.

Key Takeaways

- What it is: The systematic process of making a warehouse more efficient by improving its layout, technology, and processes to cut costs and increase speed.

- Why it’s important: To gain a competitive edge by reducing operational costs, minimizing errors, and improving overall customer satisfaction.

- When to act: It should be a continuous effort, but it’s critical when facing rising costs, high error rates, inefficient space use, or the need to scale your business.

- How to implement: Through a clear plan: analyze current operations, set goals, redesign the layout, integrate technology (like a WMS), and train your staff.

- Its benefits: Leads to significant cost reduction, higher productivity, better inventory management, and increased customer loyalty.

- Proven techniques: Includes optimizing the physical layout, streamlining order picking, implementing automation (robots/software), and using data to make smarter decisions.

- Its examples: Companies using RFID for perfect inventory tracking (like Decathlon) or rearranging high-demand products based on the season to reduce picking time.

Table of Contents

What is Warehouse Optimization?

Warehouse optimization is the continuous journey of implementing changes, such as adopting modern technology and automating tasks, to ensure a warehouse operates at its highest efficiency. It is a comprehensive strategy aimed at refining every facet of warehouse functionality, including storage, material handling, and distribution. This strategic approach involves a deep analysis of current operations to identify and rectify inefficiencies, ultimately leading to a more streamlined and cost-effective performance.

The core of warehouse optimization lies in making the best possible use of a warehouse’s space, technology, and staff. It’s not just about simplifying individual tasks but also about integrating these processes for a seamless flow of inventory. By doing so, businesses can maximize their inventory capacity and accelerate the movement of products, which in turn can boost sales and increase customer satisfaction.

Why is Warehouse Optimization Important?

Warehouse optimization has become a critical priority for companies seeking to gain a competitive edge. An optimized warehouse that runs smoothly and efficiently can serve as a strong foundation for any business involved in receiving, storing, and shipping inventory.

The importance of warehouse optimization is underscored by its ability to help businesses save costs, accelerate order fulfillment, maximize warehouse space, and improve overall customer satisfaction. Inefficient warehouse operations can lead to a host of problems, including miscounted inventory, unnecessary stock orders, and incorrect shipments, all of which can result in financial losses and damage a company’s relationship with its partners and customers.

When to Implement Warehouse Optimization

Businesses should consider implementing warehouse optimization strategies in response to several internal and external triggers. A primary indicator is when a company needs to scale its warehouse operations quickly to meet a surge in customer demand.

Other key moments to focus on optimization include:

- Rising Operational Costs: When expenses related to labor, storage, and errors begin to eat into profit margins.

- Decreased Customer Satisfaction: An increase in customer complaints about delivery delays, incorrect orders, or damaged goods.

- Inefficient Space Utilization: When the warehouse is cluttered, leading to delays, bottlenecks, and higher fulfillment costs.

- High Error Rates: Frequent mistakes in inventory counts, picking, and packing.

- Bottlenecks in Workflow: Noticeable slowdowns in specific areas of the warehouse, such as receiving or shipping.

Ultimately, warehouse optimization should be a continuous process of improvement to adapt to changing business needs and technological advancements.

How to Implement Warehouse Optimization

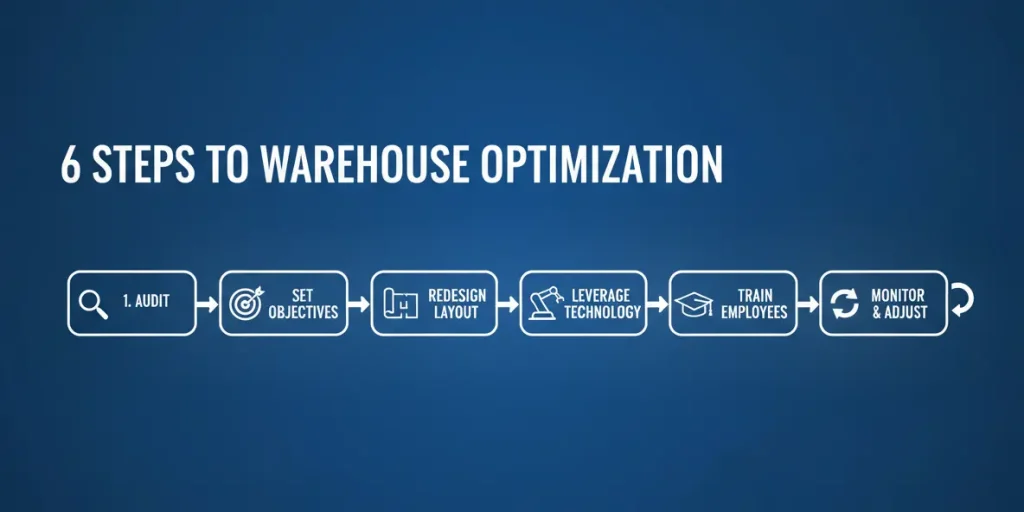

A systematic approach is crucial for the successful implementation of warehouse optimization. This involves a series of well-defined steps:

Conduct a Comprehensive Audit

Begin by thoroughly analyzing your current warehouse operations. This includes assessing the existing layout, workflows, equipment, and technology to pinpoint areas of inefficiency and identify bottlenecks.

Set Clear Objectives

Define specific and measurable goals for your optimization project. These objectives could include increasing picking efficiency by a certain percentage, reducing labor costs, or improving inventory accuracy.

Redesign the Warehouse Layout

Re-evaluate and redesign your warehouse layout to support an optimal flow of goods. This involves minimizing unnecessary movement and making the most of both horizontal and vertical space through strategic racking and shelving solutions.

Leverage Technology and Automation

Implement or upgrade to a robust Warehouse Management System (WMS) that can provide real-time data insights. Consider integrating technologies like Autonomous Mobile Robots (AMRs) and Automated Storage and Retrieval Systems (AS/RS) to reduce manual labor and increase accuracy and speed.

Optimize Inventory Management

Enhance your inventory control with effective labeling, precise tracking, and efficient storage solutions. This includes organizing inventory based on product velocity, placing high-turnover items in easily accessible locations.

Invest in Employee Training

Provide comprehensive training for all staff to ensure they are proficient in new technologies and processes. Well-trained employees are crucial for the successful adoption of optimized systems.

Monitor, Evaluate, and Adjust

Once new systems and processes are in place, continuously monitor their performance against your set objectives. Use data and feedback to make necessary adjustments and improvements, as warehouse optimization is an ongoing process.

Benefits of Warehouse Optimization

The advantages of a well-optimized warehouse extend beyond the warehouse walls, impacting the entire business positively.

Improved Operational Efficiency and Productivity

Warehouse optimization streamlines operations, which in turn boosts productivity. By organizing inventory more effectively and implementing efficient picking strategies, businesses can handle more transactions faster and with fewer mistakes.

Significant Cost Reduction

One of the most tangible benefits is substantial cost savings. By refining storage layouts, improving inventory accuracy, and streamlining processes, warehouses can minimize waste and unnecessary expenses. This also leads to lower energy costs and a reduced need for extra storage facilities.

Enhanced Customer Satisfaction

An optimized warehouse directly contributes to higher customer satisfaction. Accurate and timely order fulfillment leads to fewer errors, reducing returns and exchanges. This reliability strengthens customer trust and loyalty.

Better Inventory Management and Forecasting

With greater transparency and more accurate data on supply and demand, businesses can better predict their inventory needs. This improved forecasting prevents overstocking and stockouts, ensuring capital isn’t tied up in excess inventory.

Improved Scalability and Flexibility

Warehouse optimization is designed to be flexible and scalable, allowing businesses to accommodate growth and changes in operations without major disruptions. This adaptability is crucial for responding swiftly to market changes, seasonal demand spikes, or new product launches.

Warehouse Optimization Techniques

There are numerous techniques that businesses can employ to optimize their warehouse operations.

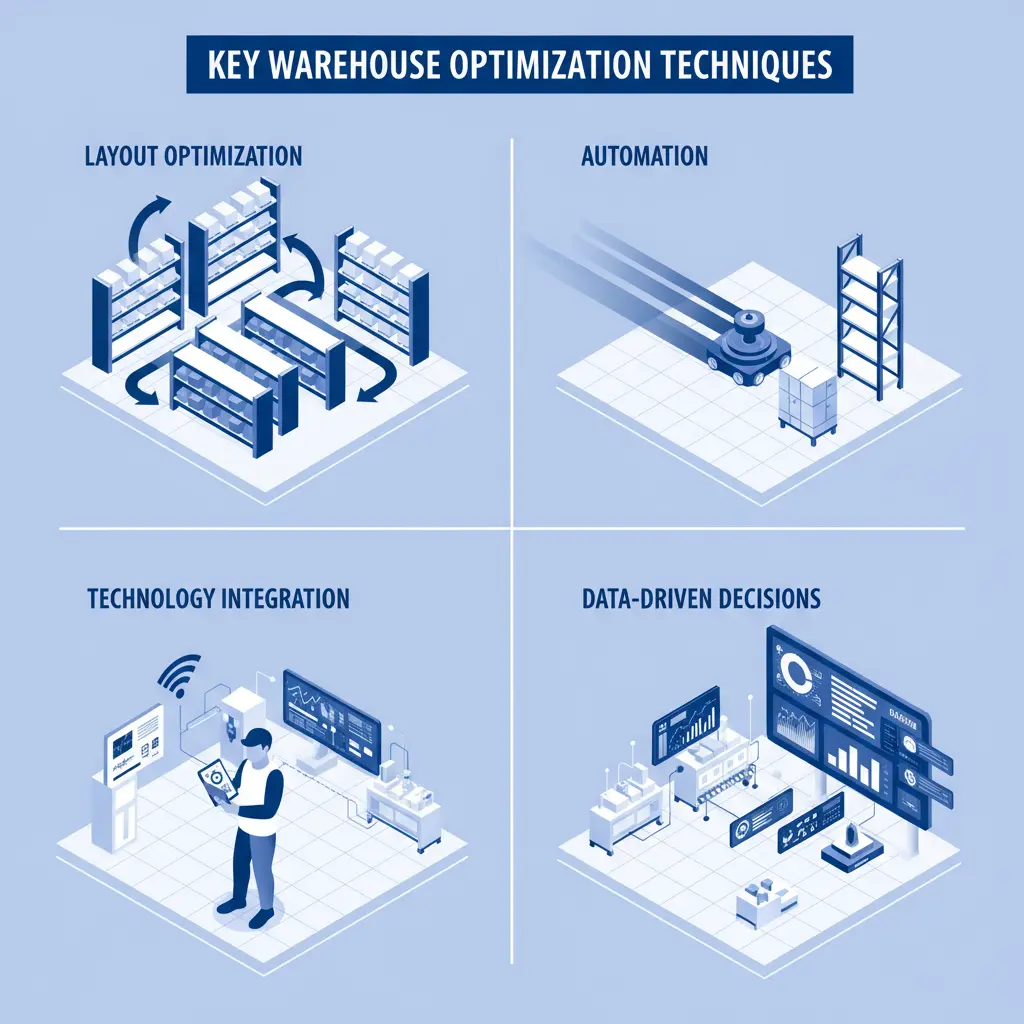

Warehouse Layout and Space Optimization

This technique focuses on designing the warehouse space to create a more effective layout and improve productivity. It often involves strategically moving items and workstations to create a more streamlined workflow. A key aspect is maximizing vertical space with taller, denser shelving units or even adding a mezzanine level.

Streamlined Order Picking

Since order picking can account for a significant portion of warehouse operating costs, streamlining this process can lead to substantial savings. Techniques like batch picking, zone picking, and wave picking can minimize travel time and boost efficiency.

Technology Integration and Automation

The integration of smart technology is a cornerstone of modern warehouse optimization. Warehouse Management Systems (WMS), scanning equipment, and inventory control software provide automation and streamlined management tools. Technologies like RFID and barcoding systems can dramatically improve inventory accuracy and fulfillment time.

Scalable Automation

Implementing scalable automation solutions like automated storage and retrieval systems (AS/RS) and autonomous mobile robots (AMRs) can help reduce labor costs, improve inventory accuracy, and increase throughput.

Maximizing Forklift Fleet Efficiency

Forklifts are critical to warehouse operations, and optimizing their use can reduce costs and improve sustainability. This includes implementing best practices like optimizing travel routes and investing in energy-efficient electric forklifts.

Data-Driven Decision Making

Utilizing data analytics offers deep insights into historical sales patterns and seasonal demand variations. This data helps in synchronizing inventory levels with actual demand, preventing both overstocking and stockouts.

Adopting Lean Principles

Applying lean warehousing practices involves eliminating waste in all forms, whether it’s wasted time, space, or resources. This results in more efficient and cost-effective operations.

Examples of Warehouse Optimization

Real-world examples demonstrate the transformative impact of warehouse optimization.

Decathlon’s Use of RFID

The sporting goods retailer Decathlon implemented RFID technology to gain 100% visibility into its inventory. Each product is tagged with a unique RFID code, and readers are used throughout their warehouses, distribution centers, and stores. This allows Decathlon to track products in real-time, dramatically improving inventory accuracy to over 95%.

Automation for a Service Provider

A US-based service provider, Overfli, addressed labor-intensive and error-prone manual inventory processes by developing a custom Android application. This app integrates with barcode scanners to automate stock verification and reporting, functioning both online and offline to ensure data integrity and streamline operations.

Seasonal Layout Adjustments

A sporting goods retailer strategically organizes its warehouse based on seasonality. In the winter, items like skis and snowboards are placed at the front of the warehouse for easy access. In the summer, the layout is adjusted to prioritize products like sunglasses and hiking shoes. This simple yet effective technique significantly reduces picking times for high-demand items.