Transverse flue spaces run between back-to-back rack rows, creating a vertical channel from floor to ceiling. Longitudinal flues run parallel to the loading aisle, separating pallets within a bay. Both are critical for fire safety, ensuring sprinkler systems can effectively suppress fires deep within storage racks.

Key Takeaways

- Location is Key: Transverse flues are between double rows; longitudinal flues are between pallets within a single row.

- Fire Safety is the Goal: Both flue types allow heat to vent upwards and, crucially, permit water from sprinklers to penetrate pallet racks and extinguish fires.

- Compliance is Mandatory: Proper flue spaces are not optional. They are mandated by fire codes, most notably the National Fire Protection Association’s standard, NFPA 13.

- Maintenance is Crucial: Simply designing flue spaces isn’t enough. They must be kept clear through proper pallet placement and warehouse management to be effective.

Table of Contents

What Are Flue Spaces? A Foundational Look

In the dense and complex world of warehouse storage, every square inch is valuable. However, squeezing products together without a plan creates a significant fire hazard. This is where flue spaces come in. Think of them as designated “breathing room” within your pallet racking structure.

A flue space is a clear, unobstructed vertical channel from the floor to the ceiling. Its primary purpose is to aid in fire prevention and suppression. When a fire breaks out within a rack, these open channels allow heat and smoke to vent upwards towards the ceiling-mounted sprinklers, triggering them faster. More importantly, they create a pathway for water from those sprinklers (or in-rack sprinklers) to travel down through the densely packed products to the base of the fire.

Without proper flue spaces, a racking structure becomes a solid block of flammable material that a sprinkler system simply cannot penetrate, rendering it ineffective. Understanding the two distinct types of flue space—transverse and longitudinal—is the first step toward a safer, more compliant warehouse.

The Transverse Flue Space Explained

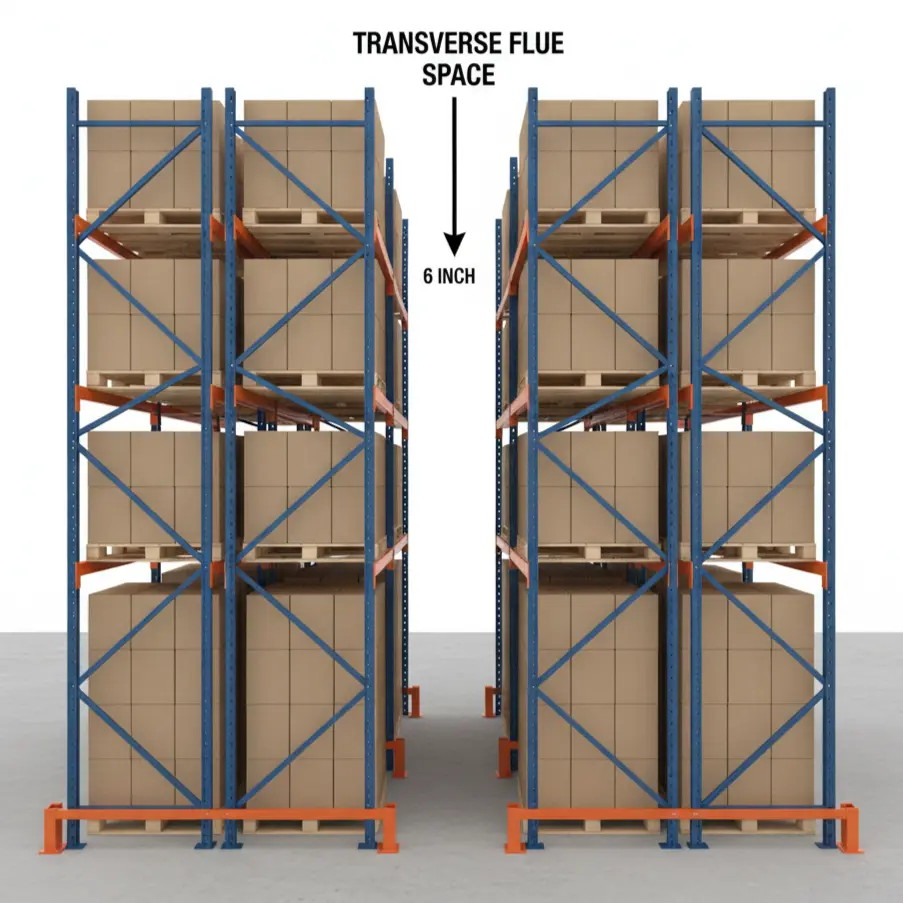

The transverse flue space is the more commonly known and visible of the two. It is the gap created between two rows of back-to-back pallet racks. When you look down an aisle, it’s the space you see separating the pallets in the row in front of you from the pallets in the row behind it.

Primary Purpose and Function

The main role of the transverse flue is to create a large, continuous vertical chimney. This serves two functions for ceiling-level sprinklers, especially high-powered ESFR (Early Suppression, Fast Response) systems:

- Heat and Smoke Venting: It allows heat from a fire deep within the racks to rise quickly and directly to the ceiling, activating the sprinklers sooner.

- Water Penetration: It provides a clear path for water from those activated sprinklers to cascade down the center of the double row, attacking the fire from above.

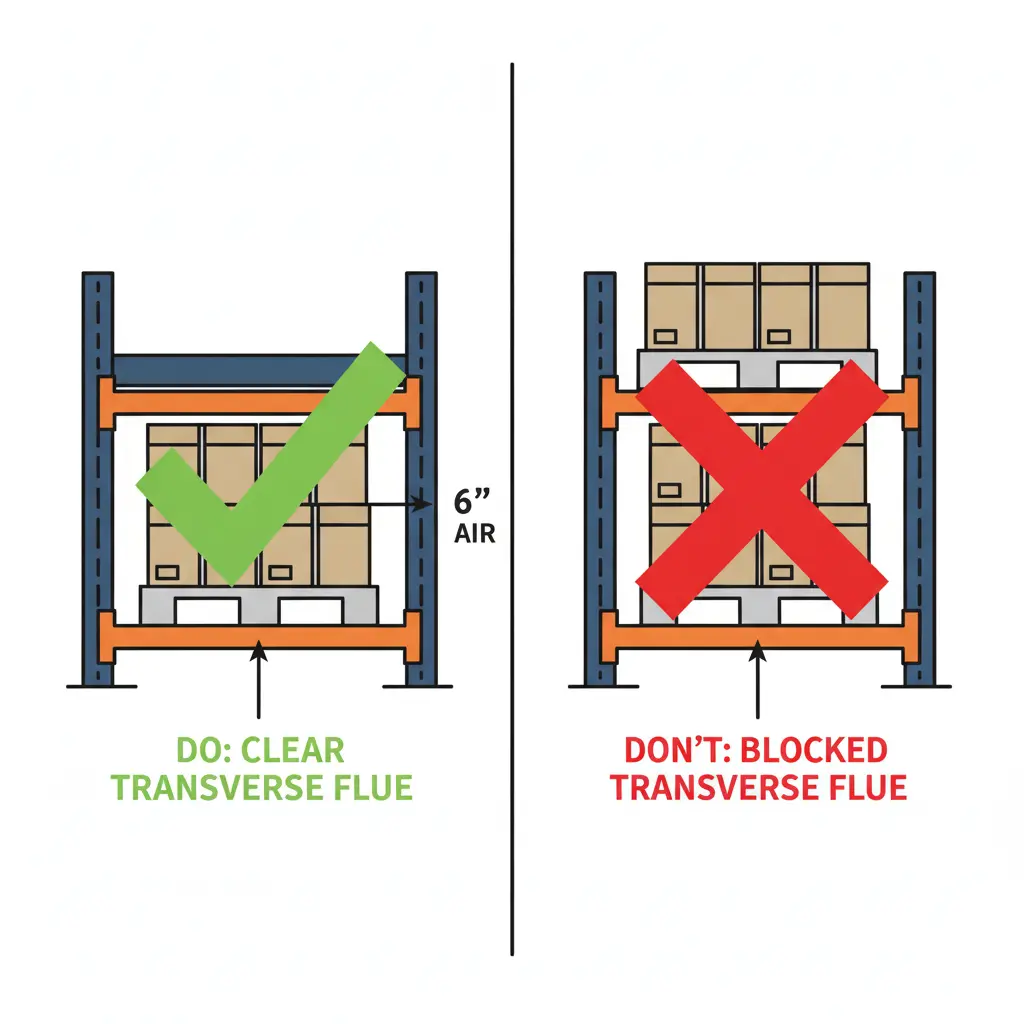

Most fire codes, including NFPA 13, typically mandate a minimum clear transverse flue space of 6 inches. This is maintained by ensuring a 3-inch overhang space behind each pallet in a back-to-back setup. This space must be kept clear at all times.

The Longitudinal Flue Space Explained

The longitudinal flue space is often overlooked but is equally critical, especially in systems with in-rack sprinklers. This space runs parallel to the direction of the loading aisle. It’s the gap created between individual pallets stored side-by-side within the same bay or shelf level.

Primary Purpose and Function

While the transverse flue helps water get down the center of a double row, the longitudinal flue helps water move sideways. If a fire starts in the middle of a wide bay, the pallets on either side can block water from reaching it. The longitudinal flue creates small, 3-to-6-inch gaps between pallets, allowing water from in-rack sprinklers to spread horizontally across the shelf level to extinguish the flames.

Maintaining this space is often more challenging than the transverse flue because it depends entirely on forklift operator precision. If an operator pushes pallets too closely together on a beam, the longitudinal flue disappears.

Head-to-Head Comparison: Transverse vs. Longitudinal Flue Space

To simplify the differences, here’s a direct comparison table:

| Feature | Transverse Flue Space | Longitudinal Flue Space |

| Location | Between back-to-back rows of racking. | Between adjacent pallets on the same shelf/bay. |

| Orientation | Perpendicular to the main loading aisle. | Parallel to the main loading aisle. |

| Primary Fire Safety Role | Vertical water penetration from ceiling sprinklers. | Horizontal water penetration from in-rack sprinklers. |

| Typical Width | 6 inches (minimum). | 3 to 6 inches (variable). |

| Maintained By | Rack design (row spacers) and pallet overhang. | Forklift operator placement. |

| Sprinkler System Interaction | Primarily supports ceiling-level/ESFR sprinklers. | Primarily supports in-rack sprinkler systems. |

Why Flue Spaces Are Non-Negotiable: The Critical Role of NFPA 13

Warehouse managers often focus on maximizing storage density, but fire codes exist to ensure this is not done at the expense of safety. The primary standard governing this is NFPA 13, the “Standard for the Installation of Sprinkler Systems.”

This document explicitly details the requirements for flue spaces based on rack height, the type of goods being stored (commodity class), and the type of sprinkler system installed. For instance, facilities using powerful ESFR (Early Suppression, Fast Response) sprinklers may avoid the need for in-rack sprinklers, but only if immaculate transverse and longitudinal flue spaces are maintained to allow the massive volume of water from ESFR heads to reach the fire source.

Failure to maintain these flue spaces can lead to catastrophic fire spread. A failed inspection can result in hefty fines, operational shutdowns, and in a worst-case scenario, the total loss of a facility.

Common Mistakes and Best Practices for Maintaining Flue Spaces

A perfect design means nothing without proper execution and maintenance.

Common Mistakes:

- Pallet Push-Through: An operator pushes a pallet too far back, encroaching on or completely blocking the transverse flue space.

- Ignoring the Longitudinal Flue: Operators push pallets tightly together side-by-side to fit more on a shelf, eliminating the longitudinal flue.

- Debris Accumulation: Shrinkwrap, broken pallet pieces, or fallen items accumulate in the flue spaces, creating obstructions and adding fuel for a fire.

Best Practices:

- Install Rack Safety Products: Use physical barriers like pallet backstops or flue keepers—wire mesh panels that attach to the back of the rack to prevent pallets from being pushed too far.

- Train Your Team: Conduct regular, documented training for all forklift operators on the importance of flue spaces and proper pallet placement.

- Conduct Regular Audits: Have a supervisor or safety manager walk the aisles weekly with the sole purpose of checking for flue space obstructions.

- Use Floor Markings: Use yellow or red tape on the floor to visually mark the transverse flue area, reminding operators to keep it clear.

Conclusion

Ultimately, the transverse vs. longitudinal flue space debate isn’t about choosing one. A safe, compliant, and well-designed warehouse racking system requires both. Proper design and consistent maintenance of these critical channels are non-negotiable for protecting your inventory, your facility, and most importantly, your people.