Description

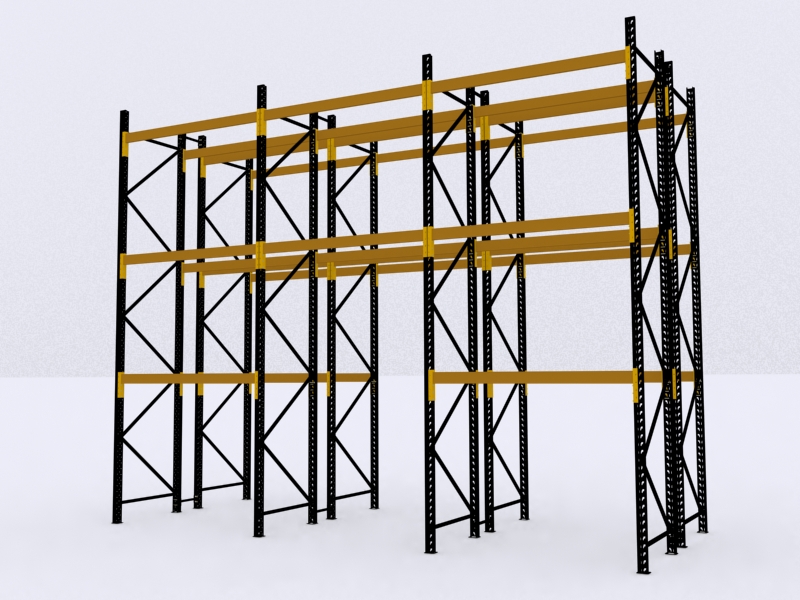

Our Drive-In Racking Systems are yet another solution to optimising warehouse space, maximising storage capacity and reducing the number of aisles. Drive-In Racking Systems are ideal for the storage of homogenous products and in applications where goods are dispatched in batches as they use the first-in-first out (FIFO) system to ensure your products do not get spoiled.

Gujrat Steel Pvt. Ltd. Drive-In Racking Systems are the most preferred solution to conventional block stacking where pallets simply cannot be stacked on top of each other.

- Size: As per requirement. Completely customisable.

- Standard colour of Uprights: Black; Standard colour of Beams: Orange.