A warehouse racking layout is the detailed plan that dictates how your storage racks are organized to maximize space, efficiency, and safety. At Gujrat Steel, we believe an optimized warehouse racking layout is the foundation of a productive facility, ensuring smooth workflow from receiving to shipping and making the most of your vertical space.

Key Takeaways

- A well-designed warehouse racking layout can dramatically increase storage density and operational efficiency.

- Start by analyzing your inventory (SKU count, size, weight) and the material handling equipment you use.

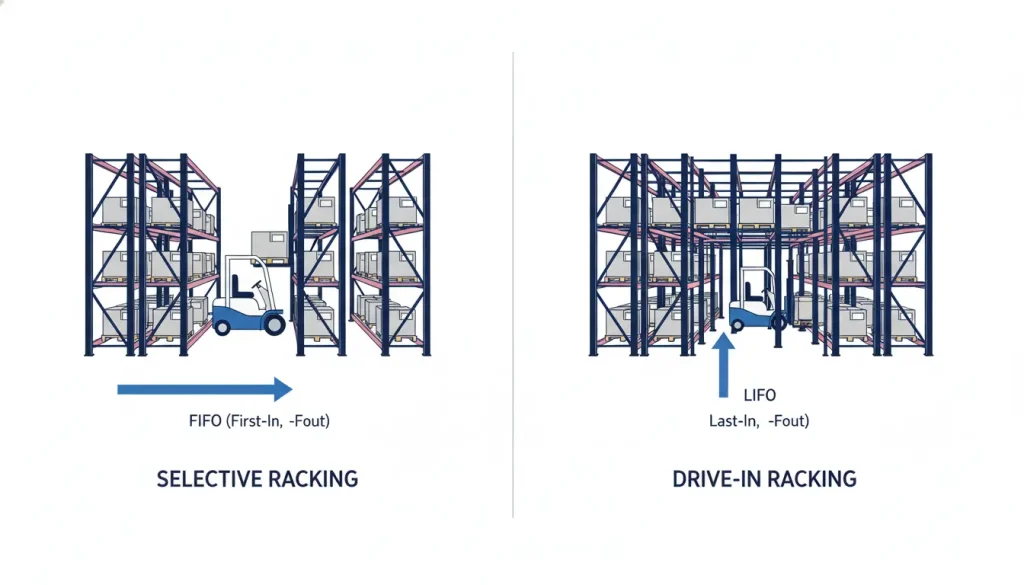

- Choose the right type of racking—like selective, double deep, or pallet flow—that aligns with your inventory rotation needs (FIFO/LIFO).

- Ensure your layout includes adequate aisle width for forklifts and adheres to all safety regulations.

- Always plan for future growth by designing a flexible and scalable warehouse racking layout.

Table of Contents

Why a Strategic Warehouse Racking Layout is a Game-Changer

Here at Gujrat Steel, we don’t just sell steel; we provide the backbone for your entire operation. A warehouse is more than just a building; it’s a dynamic environment where efficiency is measured in seconds and inches. The single most important factor influencing this efficiency is your warehouse racking layout.

An optimized plan does more than just create neat rows of shelves. It streamlines every process, reduces travel time for your staff, minimizes product damage, and creates a safer working environment. Without a proper warehouse racking layout, you’re likely facing operational bottlenecks, wasted space, and lost revenue.

In this guide, we’ll walk you through the essential steps and strategies to design a layout that transforms your warehouse into a high-performance asset. Let’s build a foundation for success together.

Step 1: Analyze Your Space and Inventory

Before you can even think about drawing up a plan, you need to understand the canvas you’re working with and what you’ll be storing. A successful warehouse racking layout is built on data, not guesswork.

Start by getting precise measurements of your facility. Note the total square footage, ceiling height, and the location of any obstacles like support columns, dock doors, or office spaces. This will define the physical constraints of your design.

Next, conduct a thorough inventory analysis. You need to know your average number of Stock Keeping Units (SKUs), the dimensions and weight of your typical pallets, and your inventory turnover rate. This information will determine the type of racking you need and the overall density of your layout. For more on this, our guide to warehouse inventory management is a great starting point.

Step 2: Choosing the Right Racking System

With your data in hand, the next step is selecting the appropriate racking. The type of racks you choose is fundamentally linked to your warehouse racking layout. Each system has a different footprint and is designed for specific inventory management methods.

At Gujrat Steel, we offer a variety of warehouse racking systems to suit any need. For example, if you need access to every pallet at all times (First-In, First-Out or FIFO), Selective Racking is the ideal choice. It’s versatile and perfect for warehouses with a high SKU count.

However, if storage density is your top priority and you operate on a Last-In, First-Out (LIFO) system, Drive-In or Double Deep Racking might be more suitable. These systems reduce the number of aisles, allowing you to store more products in the same footprint. Our blog post on Drive-In vs. Drive-Through Racking can help you understand these high-density options better.

A Perfect Warehouse Racking Layout Requires the Right Racks

Making the right choice here is critical. Pallet Flow Racking, for instance, is excellent for FIFO operations with high-volume, perishable goods, as it uses gravity to move pallets along rollers. Conversely, Push Back Racking is a great LIFO solution for increasing density. The key is to match the system to your product flow, a core principle of a successful warehouse racking layout.

For a full overview of your options, we highly recommend reading our guide on the different types of steel warehouse storage racks. This resource will provide the detailed knowledge you need to make an informed decision for your facility.

Remember, the goal is to find a balance between storage density and accessibility that works for your unique operation. A well-thought-out warehouse racking layout depends entirely on this choice.

Step 3: Designing the Warehouse Racking Layout

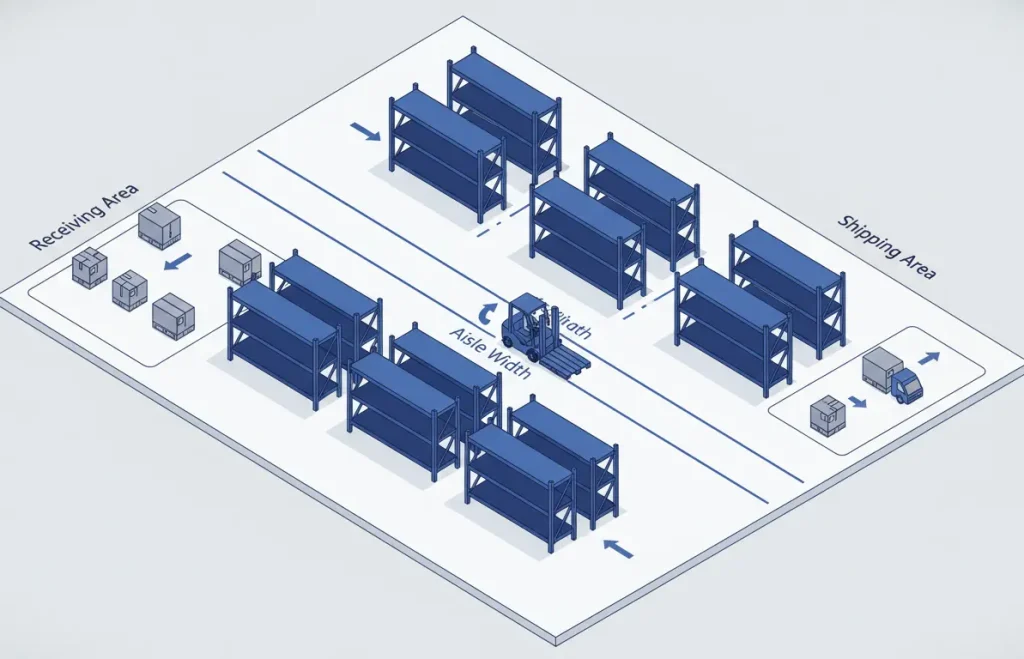

Now it’s time to bring it all together and design the actual layout. This is where you map out the placement of racks, aisles, and operational zones.

Aisle Width is Crucial

One of the most critical elements in your warehouse racking layout is aisle width. The width will be determined by the type of material handling equipment you use, such as forklifts or reach trucks. You must allow enough space for them to navigate safely and efficiently.

Standard aisles are typically 10-12 feet wide, but for greater storage density, you might consider a Very Narrow Aisle (VNA) layout. VNA layouts can significantly increase your storage capacity but require specialized forklifts. Always refer to the equipment manufacturer’s specifications when determining aisle width.

Creating Zones for Efficiency

A great warehouse racking layout divides the facility into functional zones. This includes areas for receiving, put-away, picking, packing, and shipping. By organizing your warehouse this way, you create a logical and efficient workflow.

Place your fastest-moving inventory in the most accessible locations, closest to the shipping doors, to minimize travel time. This concept, known as slotting, is a key part of warehouse optimization. We cover this and other strategies in our blog on tips to achieve warehouse efficiency.

Safety Considerations for Your Warehouse Racking Layout

Safety should never be an afterthought; it must be integrated into your warehouse racking layout from the very beginning. This includes ensuring proper clearance between racks and sprinkler systems and installing adequate lighting throughout the facility.

Your layout must comply with all local fire codes and workplace safety regulations. Be sure to include clear pathways for pedestrian traffic and emergency exits. For an in-depth look at this topic, please read our essential guide on warehouse racking safety.

Proper installation is also a matter of safety. A poorly installed rack can lead to catastrophic failure. That’s why understanding the process, as detailed in our pallet racking installation guide, is so important for the integrity of your entire system.

The Future: A Flexible Warehouse Racking Layout

Your business is going to grow, and your storage needs will change. A static warehouse racking layout can quickly become obsolete. The best designs are both scalable and flexible.

Think about how your layout can be adapted in the future. Using modular racking systems can make it easier to reconfigure your space as your SKU profile or inventory volume changes. Building flexibility into your initial warehouse racking layout will save you significant time and money down the road.

Consider leaving some open floor space for temporary staging or future expansion. Planning for growth from day one is the hallmark of a strategic and forward-thinking operation. This proactive approach is a cornerstone of effective warehouse optimization.

Conclusion

Ultimately, a well-executed warehouse racking layout is the blueprint for your operational success. By carefully analyzing your space, choosing the right systems, and designing for efficiency and safety, you can create a highly productive environment. At Gujrat Steel, we’re committed to providing the durable racking solutions you need to bring that optimal warehouse racking layout to life.