Stainless steel is a type of iron-based metal alloy specifically known for its high resistance to rust and corrosion. This property comes from adding a minimum of 10.5% chromium, which forms a protective surface layer.

Key Takeaways

- It’s Mixed Metal: Not pure iron. It’s steel (iron + carbon) mixed with chromium. That’s key.

- No Rust (Mostly): Its big superpower? It fights off rust and stains like crazy.

- Chromium’s the Hero: Gotta have enough chromium (at least 10.5%) for the magic to work.

- Lots of Kinds: It’s not just one thing. Many different recipes (“grades”) exist for different jobs.

- It’s Everywhere: Seriously. Kitchens, hospitals, cars, buildings… look around!

Table of Contents

Introduction

Stainless steel. You see it all the time. Shiny sinks. Forks and knives that don’t go brown. Maybe railings that gleam in the sun. It’s everywhere! We know it looks clean and doesn’t get rusty like old tools left outside. But what is it? What makes it ‘stainless’? Is it different from just regular steel? And why do people talk about different ‘types’ of it? It’s actually pretty clever stuff, how they make metal that fights off rust. Let’s break down what stainless steel is all about, in plain English.

Okay, What’s the Basic Deal? Steel Minus the Rust Problem.

First up: regular steel. What is it? Mostly iron. Add a tiny bit of carbon, and bam, you get steel. Super strong. Useful stuff. But it has one massive headache: rust. Leave it out in the rain, heck, just leave it in damp air, and it starts getting that ugly orange-brown flaky coating. That’s rust. It eats the metal away.

Now, stainless steel. Still mostly iron. Still got some carbon. But it has a special friend added to the mix: chromium. This is the game-changer. For steel to get the ‘stainless’ badge, it needs at least 10.5% chromium mixed in. Lots of types have even more than that.

How Does Chromium Do Its Anti-Rust Magic?

This is the cool part. Chromium is like a superhero bodyguard for the iron. Here’s the trick:

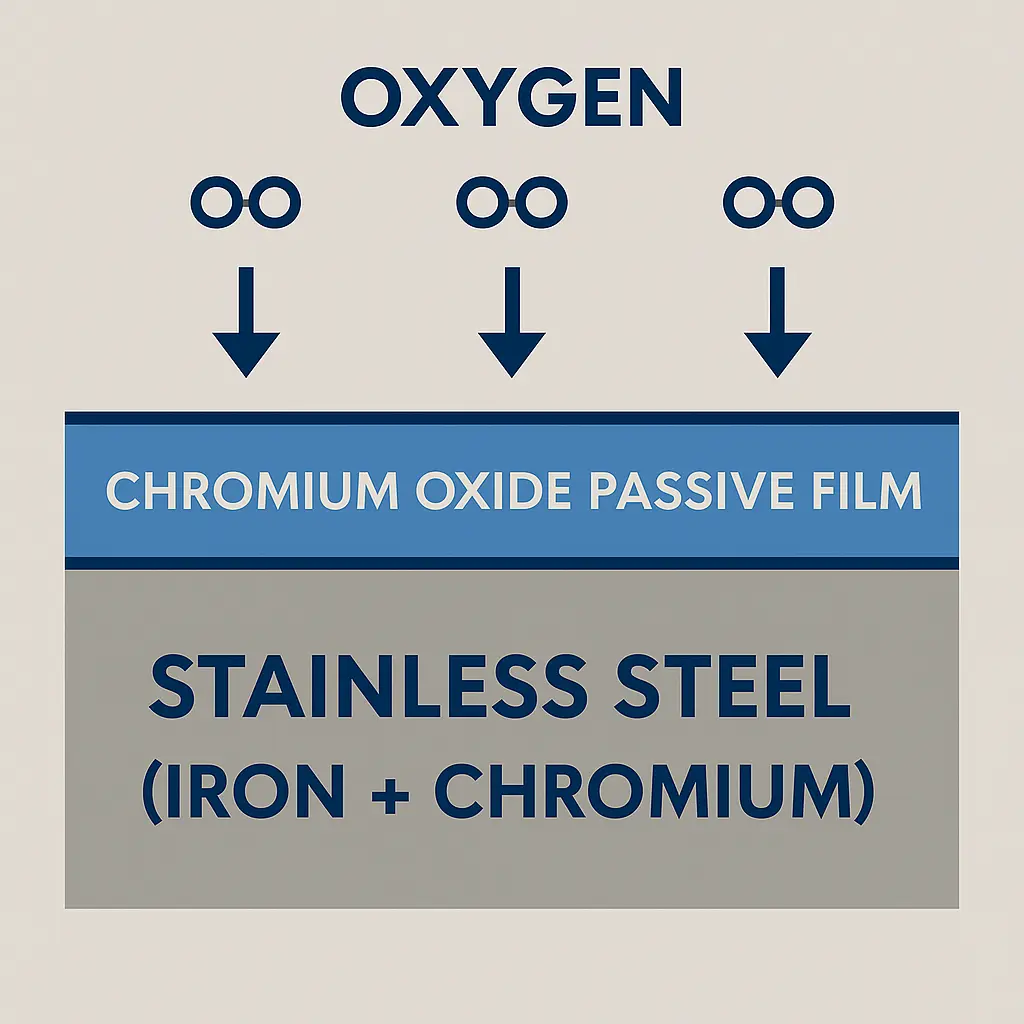

When you have enough chromium mixed into the steel, and that steel meets oxygen (which is everywhere, right? Air, water…), the chromium on the very surface instantly reacts with the oxygen. It forms this super-thin layer all over the steel. You can’t even see it! It’s called the chromium oxide passive film.

Think of it like an invisible, super-tough raincoat for the metal.

- It’s Tough: This invisible layer is really stable. Doesn’t react easily.

- It Heals Itself!: Get this – if you scratch the stainless steel, the ‘raincoat’ breaks. But the chromium underneath instantly reacts with oxygen again and repairs the layer over the scratch! Like magic.

- It Stops Rust: This raincoat layer blocks oxygen and water from getting to the actual iron underneath. No oxygen reaching the iron = no rust forming.

That’s the secret! It’s constantly protecting itself with this invisible, self-healing shield. Pretty neat, huh?

Not Just Iron and Chromium: Other Ingredients in the Mix

While iron and chromium are the stars, steelmakers often toss in other metals (making it an ‘alloy’ – a metal mix) to give stainless steel different powers:

- Nickel: You hear about this one a lot (like in “18/8” stainless). Nickel makes the steel easier to bend and shape without breaking, makes it tougher (especially when it’s really cold), and bumps up the rust protection even more, especially against certain acids.

- Molybdenum: This is like kryptonite for rust caused by salt! Add some molybdenum (like in grade 316 stainless), and it gets way better at resisting corrosion from saltwater, road salt, stuff like that. That’s why they call 316 “marine grade.”

- Manganese: Sometimes used instead of some nickel (nickel can be pricey). Can make the steel stronger too.

- Nitrogen: Also makes it stronger and helps fight off certain kinds of corrosion damage.

- Others: Tiny bits of silicon, copper, titanium, and other stuff might get added to tweak things like how easy it is to weld, how strong it is, or how well it handles heat.

Which extra ingredients they add, and how much, decides the exact ‘grade’ of stainless steel and what it’s best at doing.

Different Stainless Steel Types: It’s Complicated!

Because you can mix these metals differently, and even change how the metal crystals line up inside with heat, stainless steels get grouped into different ‘types‘ (sometimes technically called families). Think of it like dog breeds – all dogs, but different types for different things. Here are the main ones:

1. Austenitic Stainless Steels

- What’s In ‘Em?: Chromium AND nickel are the key extras here. Often some manganese or nitrogen too.

- Famous Grades: 304 (your typical kitchen sink/cookware stuff, often called “18/8” for ~18% chromium, ~8% nickel). Also 316 (the one with molybdenum for salt resistance).

- What They’re Like: Usually not magnetic. Fight rust really well. Easy to shape and weld. Stay tough even when freezing cold. You can’t make them harder with heat, but bending or stretching them makes them stronger.

- Used For: Everything! Kitchen stuff, food factories, chemical tanks, shiny building panels, railings, car trim, even medical implants. Super common.

2. Ferritic Stainless Steels

- What’s In ‘Em?: Got chromium, but little or no nickel. Their insides look more like regular steel.

- Famous Grades: 430 (maybe on your car’s shiny trim or inside your dishwasher), 409 (often used for car exhausts).

- What They’re Like: They ARE magnetic. Pretty good rust resistance (but maybe not as good as the 300-series stuff in tough spots). Decently strong. Cheaper than the ones with nickel. Can get brittle if they get super hot or cold. Can’t be hardened with heat.

- Used For: Car exhausts, some appliance parts, kitchen counters, places where you need decent rust resistance but don’t need the absolute best (or the high cost of nickel).

3. Martensitic Stainless Steels

- What’s In ‘Em?: Got chromium, but also more carbon than the other types. Very little nickel, if any.

- Famous Grades: 410, 420 (think knives, surgical tools).

- What They’re Like: They ARE magnetic. Okay rust resistance (less than the others). But! Their superpower is you can make them super hard by heat treating them, just like regular tool steel. This means they can hold a really sharp edge.

- Used For: Knives, scissors, surgical tools, dental tools, valve parts – anything needing to be hard and sharp, plus reasonably rust resistant.

4. Duplex Stainless Steels

- What’s In ‘Em?: A mix! They have bits of both austenitic and ferritic structures inside. Lots of chromium, some nickel, often molybdenum and nitrogen too.

- Famous Grades: 2205 is a common one.

- What They’re Like: Really strong (often stronger than common 304/316). Excellent rust resistance, especially against certain types of damage that can affect the 300-series in salty or warm water. They ARE magnetic. Weld pretty well.

- Used For: Tough jobs. Chemical plants, paper mills, offshore oil rigs, boat parts, bridges – places needing high strength and top-notch corrosion resistance.

5. Precipitation-Hardening (PH) Stainless Steels

- What’s In ‘Em?: Chromium and nickel, plus small amounts of other stuff like copper or aluminum. These extras let them get hardened by a special heating process (called precipitation or age hardening).

- Famous Grades: 17-4 PH is well-known.

- What They’re Like: Can be made incredibly strong through heat treating, while still being pretty good against rust (often better than martensitics). They ARE magnetic.

- Used For: Airplane parts, strong shafts, gears – places needing serious strength plus good rust fighting ability.

Why Use Stainless Steel? What Makes It Good?

So why pick stainless over regular steel or maybe aluminum? Lots of reasons:

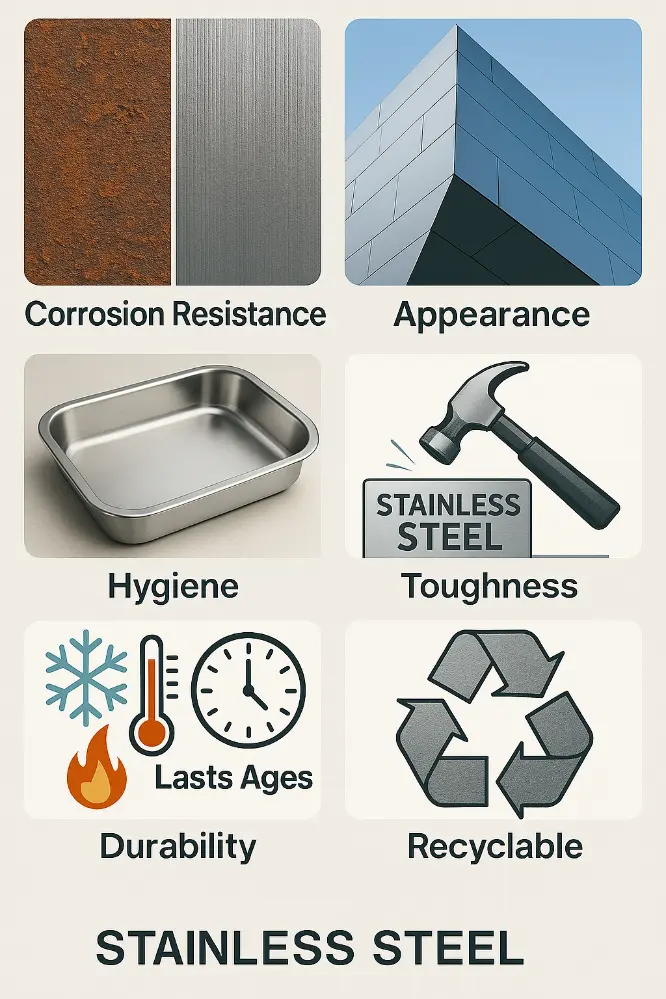

- Rust? Nope! That’s the big one. It just doesn’t rust or stain easily. Huge advantage.

- Looks Good: It has that clean, bright look. Can be shiny like a mirror or have a soft brushed finish. Stays looking nice for ages.

- Clean & Hygienic: The surface is smooth, doesn’t have tiny pores for germs to hide in easily. That’s why it’s awesome for kitchens, hospitals, food places. Easy to clean.

- Tough Enough: It’s strong, holds up to bangs and bumps pretty well.

- Handles Heat (and Cold): Many types work well when things get hot OR really cold without getting weak or rusty.

- Lasts Ages: Because it doesn’t rust away, things made from it can last a very long time. Might cost more upfront, but cheaper in the long run.

- Recycle It!: Stainless steel is 100% recyclable. You can melt it down and make new stuff out of it again and again without losing quality. Good for the planet.

Anything Bad About It?

It’s great stuff, but not perfect for every situation:

- Costs More: Usually more expensive than plain old carbon steel. Chromium and especially nickel aren’t cheap.

- Heavy Stuff: Still mostly iron, so it weighs a fair bit compared to aluminum or plastic.

- Tricky to Work With Sometimes: Some types can be harder to cut, drill, or weld smoothly compared to regular steel. Might need special tools or skills.

- Doesn’t Move Heat Well: Not great at transferring heat quickly. That’s why fancy pots might have a copper bottom stuck onto a stainless steel body – copper moves heat fast, steel is durable and easy to clean.

- Not Totally Invincible: While it resists rust incredibly well, super harsh chemicals or specific nasty environments (like constantly being in chlorine bleach) can still damage it, especially the less fancy grades.

Wrapping Up: Tough, Shiny, and Everywhere

So, that’s the story of stainless steel. It’s not just one metal, but a whole team of iron-based mixes starring chromium. That chromium gives it the amazing power to fight off rust by creating an invisible, self-healing shield. Add in other ingredients like nickel or molybdenum, and you get different families with different strengths – some super formable, some super hard, some extra tough against salt. It’s used everywhere because it looks good, stays clean, resists rust, and lasts a long time. Sure, it costs more than basic steel, but its toughness and long life often make it worth it. Pretty clever stuff, that shiny metal!